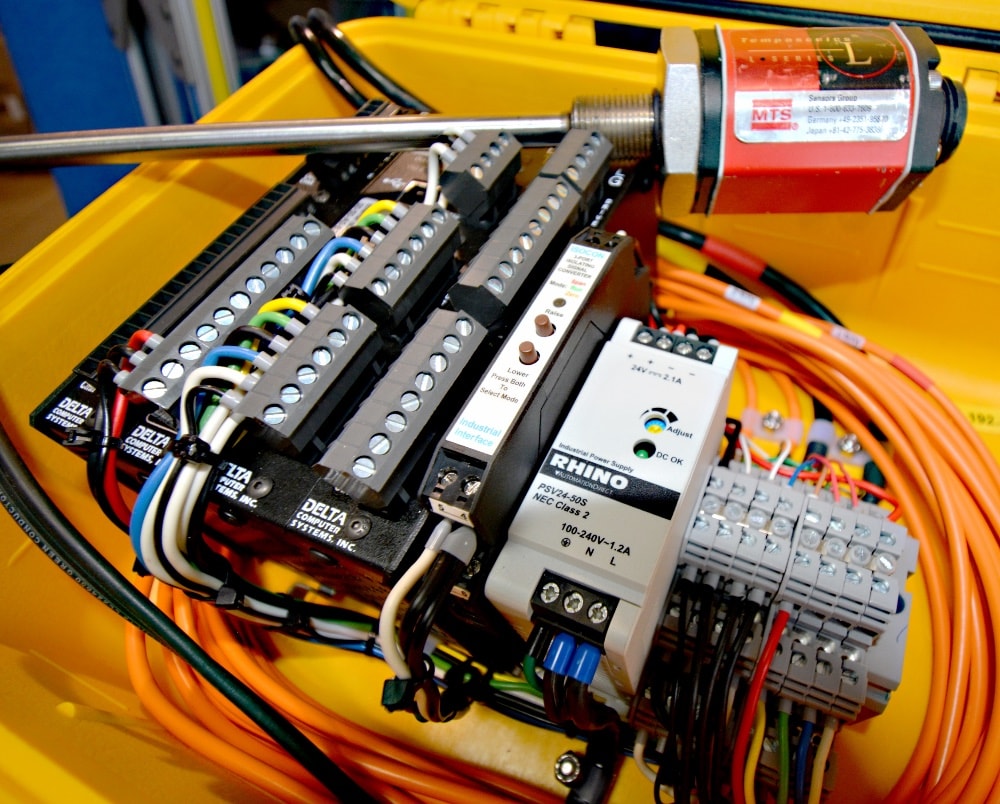

MAGNETOSTRICTIVE DISPLACEMENT TRANSDUCERS

Objective: Explain the operating principles of an MDT and perform basic tests

Activity: Check cabling and test for normal functioning

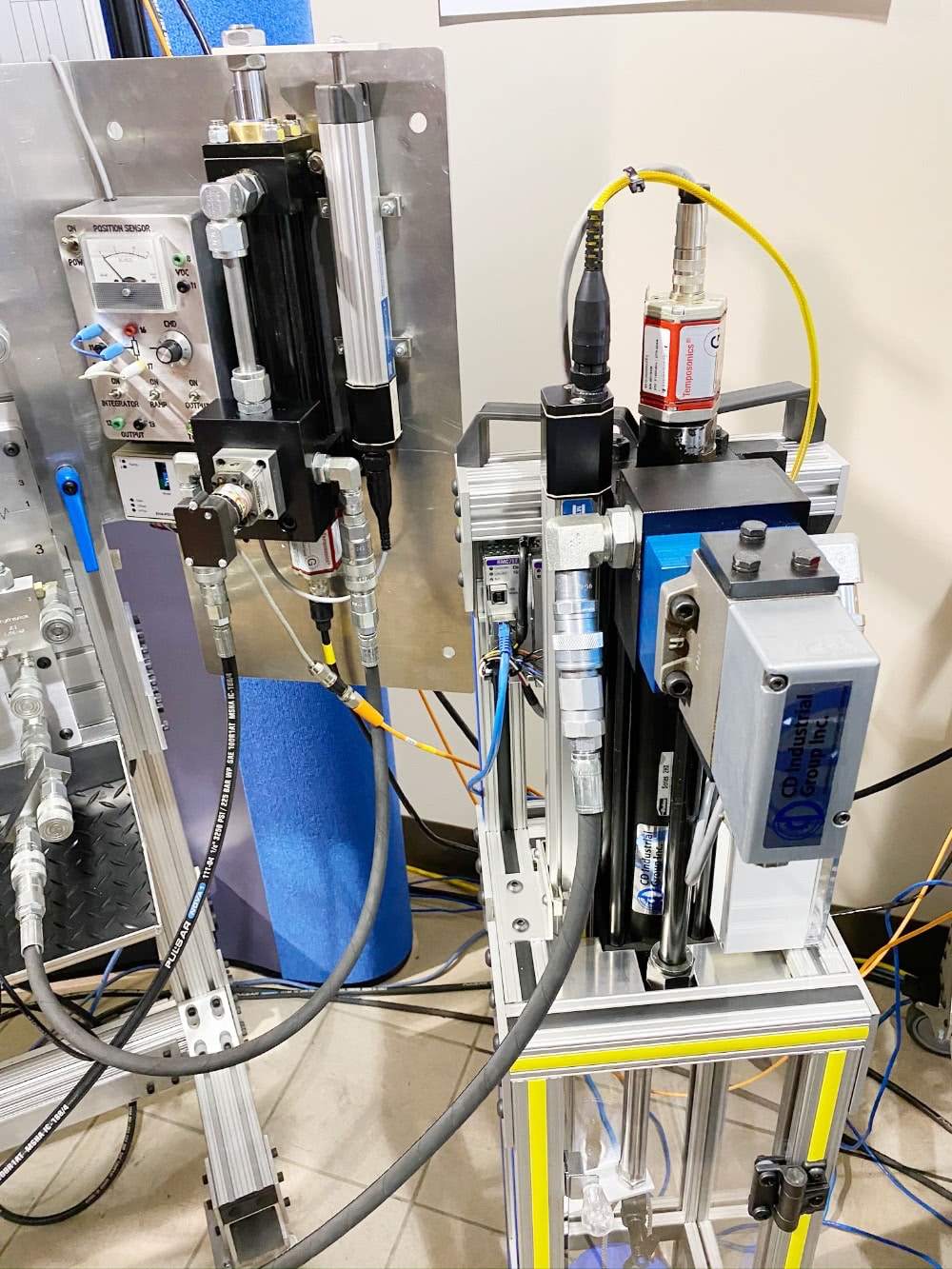

DEDICATED MOTION CONTROLLER

Objective: Setup and configure a Delta RMC or 1756-HYD02 motion controller

Activity: Setup travel range and use the PID wizard for tuning

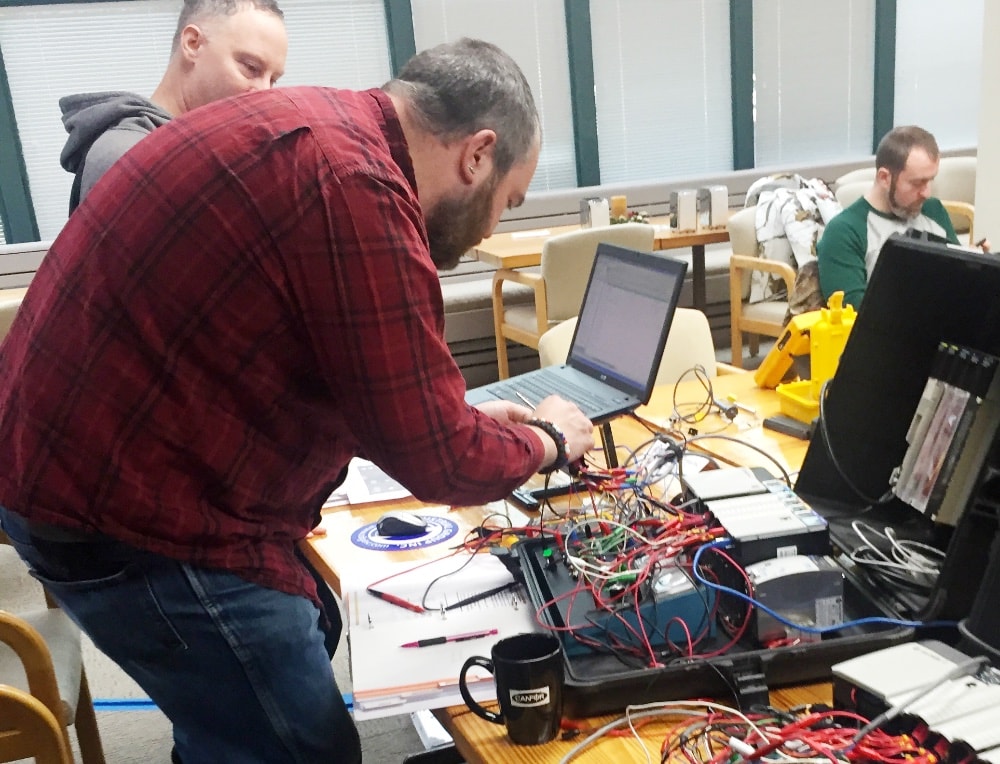

CONTROLLOGIX HARDWARE SETUP

Objective: Configure ControlLogix hardware for use in motion control projects

Activity: Configure processor, Ethernet module & field wiring

SETUP CONTROLLOGIX PLC TO CONTROL DELTA MOTION CONTROLLER

Objective: Implement control of a Delta RMC sequence using instructions from the PLC

Activity: Establish and test data sharing communications between PLC and Delta

ANALYZE TYPICAL MOTION CONTROL PROBLEMS

Objective: Follow a logical method for motion control, problem solving

Activity: Solving for issues related to vibration and shock