Upcoming Courses

How to Maintain & Troubleshoot Hydraulic Systems

Red Deer, Alberta

February 17–19, 2026

Request A Course

Book us for a public or private course.

Take a look at our catalog below, then...

Our instructors draw on their extensive industrial experience to teach and challenge your team. Learning is an active process, with students at every skill level using computer simulations and real live industrial equipment. We emphasize systems thinking, reliability-centered maintenance, and advanced diagnostic techniques. Students come away from our courses with a solid understanding of how systems are designed and how the individual components behave and relate, ready to make a confident and valuable contribution. If you need higher performance, sharper analysis, and deeper troubleshooting skills, these courses are going to deliver. - Carl Dyke, CEO

Popular Courses

Practical Hydraulics

Hands-on review of flow, pressure, and directional control valves, system adjustments, pump basics, as well as safe work practices.

How To Maintain & Troubleshoot Hydraulic Systems

This highly concentrated course gives you a solid understanding of hydraulic principles, and component design & behaviour.

Mobile Equipment Electrical Troubleshooting

The first step in rigorous, analytical electrical troubleshooting training for mechanics.

ControlLogix & RSLogix 5000 Basics

Gain experience with the functions, architecture, and software in use in the ControlLogix PLC platform.

ControlLogix & RSLogix 5000 Intermediate

Basic PLC network troubleshooting and analog I/O skills. Configure a complete mill network of PLCs, and learn how to recover it after an outage.

ControlLogix & RSLogix 5000 Advanced

A deep study in RSLogix 5000 to learn how and why well-built, well-programmed systems perform at their best.

Complete Course Catalog

Show

Fluid Power Training

Pneumatics Maintenance & Troubleshooting

Participants come away from this highly concentrated course with a solid understanding of pneumatic principles, and component designs and functions.

Practical Hydraulics

Hands-on review of flow, pressure, and directional control valves, system adjustments, pump basics, as well as safe work practices.

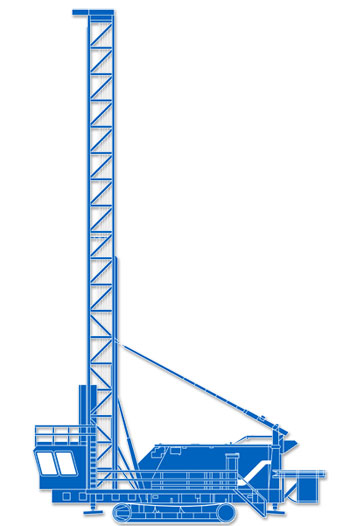

Blast Hole Drills

Learn to maintain and troubleshoot the hydraulic systems in Bucyrus 49HR (Caterpillar MD664) and P&H 120A blast hole drills.

Dozers & Excavators

Go hands-on with live hydraulic components, simulations, and interactive schematics. Learn the typical circuits, sub-circuits, and operating parameters.

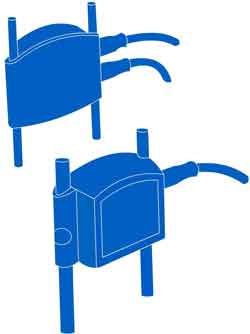

Fundamentals of Crane Hydraulics

Hydraulic principles, component functions, analysis, and troubleshooting skills are taught with Live Schematic simulations and hands-on equipment from typical mobile crane systems.

Haul Truck Hydraulics

Haul truck technicians and mechanics — learn to find and verify faults safely, accurately, and efficiently.

How To Maintain & Troubleshoot Hydraulic Systems

This highly concentrated course gives you a solid understanding of hydraulic principles, and component design & behaviour.

Hydraulic Shovel Maintenance & Troubleshooting

With a careful examination of major pump groups, pressure controls as well as pilot and directional valving, participants learn to verify correct and normal hydraulic shovel functions.

Hydraulic System Maintenance & Troubleshooting for Coiled Tubing

Gain a deeper understanding of injector control and reel drag hydraulics.

Hydraulics for Slickline & Wireline Units

A hands-on session on winch control and hydrostatic hydraulics.

Hydraulics for Wind Turbines

This highly customizable course examines the circuits that govern blade pitch, rotor braking, and yaw.

Hydro Station Power Intake Gates

Explore the hydraulic systems that control hydro station, power intake gates, and spillway gates.

Hydrostatic Drive Troubleshooting Boot Camp

Get a solid understanding of hydrostatic drive principles, critical components and adjustments, as well hydraulic and electric pump displacement piloting.

Loaders & Graders

Learn to maintain and troubleshoot loader and grader systems for maximum availability and reliability.

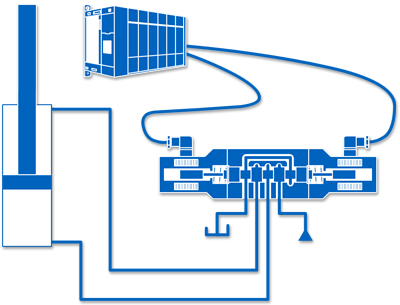

Pulp & Paper Mill Hydraulics

By the end of this training week, your maintenance team will be safely testing, adjusting, and maintaining mill systems.

Sawmill Hydraulics

A week-long intensive study of reliability-centered system maintenance. Learn our highly effective approach to troubleshooting, and practice hands-on with our hydraulic training panels and Live Schematic simulations.

Advanced Hydraulics Troubleshooting & Motion Control

Understand the internal workings of complex hydraulic motion and pressure controls, and the right adjustments for proper operation. Then, learn an effective, methodical approach to troubleshooting for when tough problems arise.

Advanced Mobile with Load Sense Hydraulic Troubleshooting

Cut through the complexity of Load Sense with our live hydraulics training panels, advanced system simulation software, oilfield and mobile machinery schematics, and hands-on study of individual cut-away hydraulic components.

Hydro Turbine Governor Hydraulics

Gain clarity on the servo-hydraulic governor systems used on hydroelectric turbines.

Electrical & Instrumentation

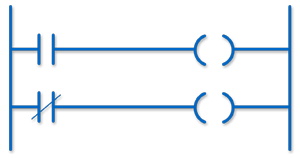

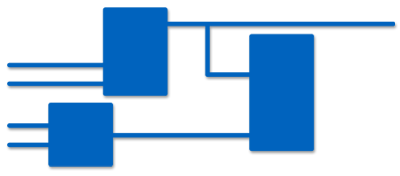

ControlLogix & RSLogix 5000 Basics

Gain experience with the functions, architecture, and software in use in the ControlLogix PLC platform.

PLC5 & SLC500 with RSLogix Basics

A comprehensive, hands-on program using a hardware rack, and simulations of RSLogix with visual layout and animation of actual machinery.

ControlLogix & RSLogix 5000 Intermediate

Basic PLC network troubleshooting and analog I/O skills. Configure a complete mill network of PLCs, and learn how to recover it after an outage.

PLC5 & SLC500 with RSLogix Advanced

Go deeper into analog functions and high-speed data handling, with our hands-on circuitry lab and software layout environment.

ControlLogix & RSLogix 5000 Advanced

A deep study in RSLogix 5000 to learn how and why well-built, well-programmed systems perform at their best.

Mobile Electrical & Electronic

Mobile Equipment Electrical Troubleshooting

The first step in rigorous, analytical electrical troubleshooting training for mechanics.

Sensor Electronics

Become a mobile equipment technician who can identify sensors, explain their function, wiring configuration, and signal type, and then conduct diagnostic tests.