Great material with the best learning tools I have had in a training course.Brent D., Catalyst Paper

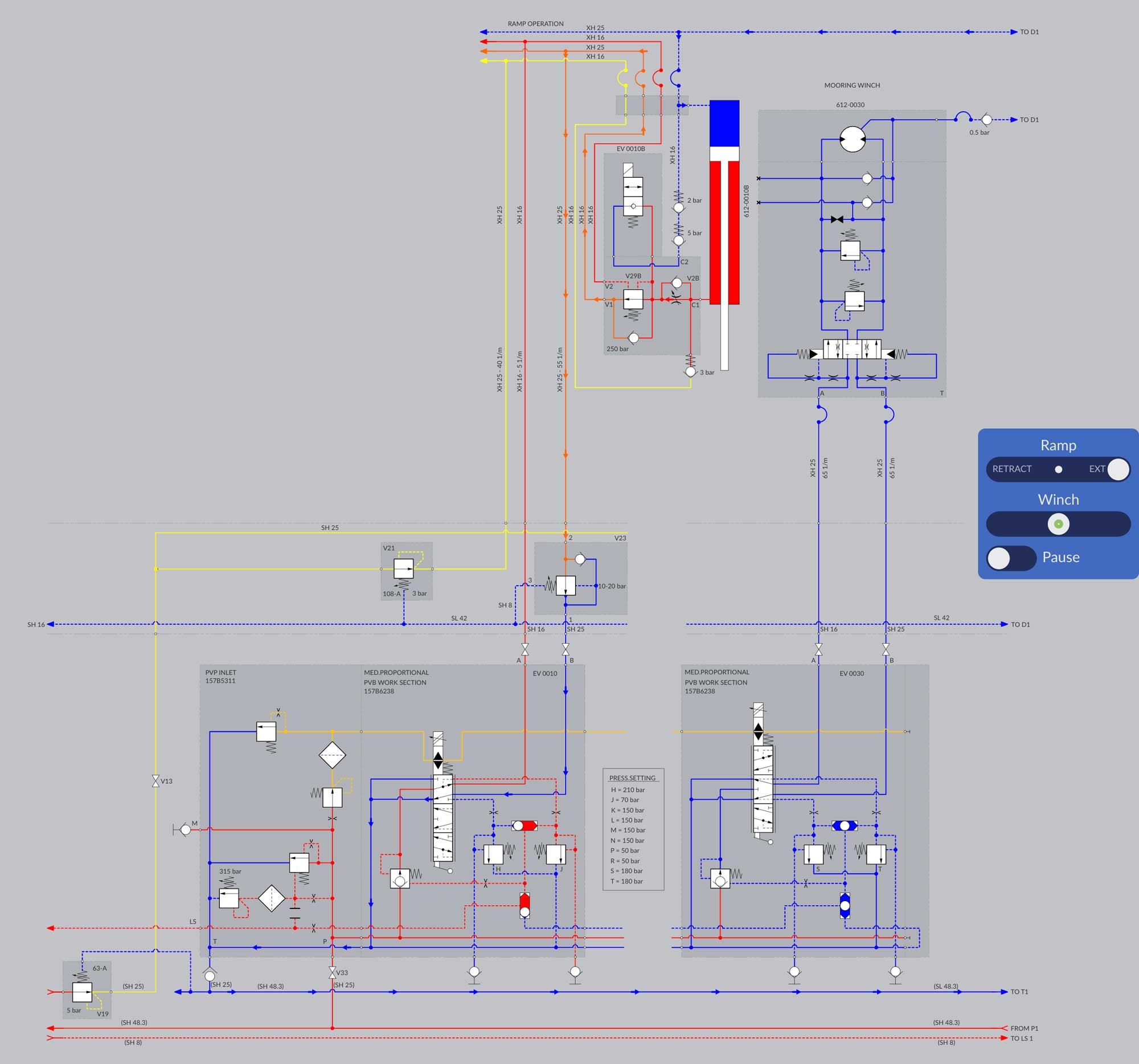

Paper Reeling System

Objective: Interpret the schematics and pressure settings for a paper reeling system

Activities: Test flow divider performance to establish proper, parallel cylinder synchronization

Establish testing procedures for closed loop, hydraulic pressure control

My reading and understanding of hydraulics prints is much better now. Great instructor that shows knowledge without arrogance. Speaks to the class at their level.Karl S., Tolko Kraft Papers

Chip Truck Dumper

Objective: Explain the critical functions of truck dumper systems

Activities: Create schematic based diagnostic tools for these telescopic cylinder circuits

Learn the cartridge & unloader valves that provide fast lowering

I learned to troubleshoot slab press problems more efficiently.Bill S., Millar Western Pulp

Pulp Washer

Objective: Identify the components of the pulp washer hydrostatic circuit

Activities: Test for correct pump stroke function and correct pre-charge pressure

Solidify your skills with large, closed circuit, radial piston motor drives

One of the best in-house courses I've been on. Great instructor who kept things interesting.Darren H. Catalyst

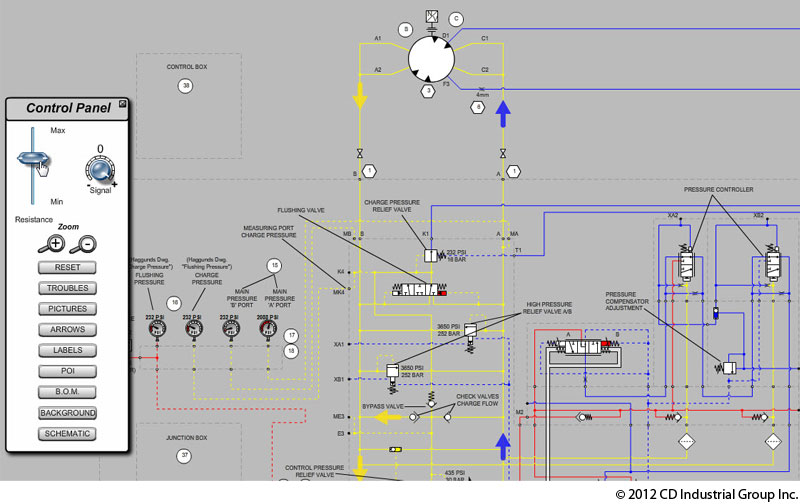

Stoker - Reclaim - Shaker

Objective: Identify the unique components in use for load sense hydraulics

Activities: Test valve amplifiers and electro-hydraulics proportional valves

Test margin pressure settings with confidence

Extremely good. Starts basic and then moves slowly and thoroughly.Tim S., Meadow Lake Mechanical Pulp

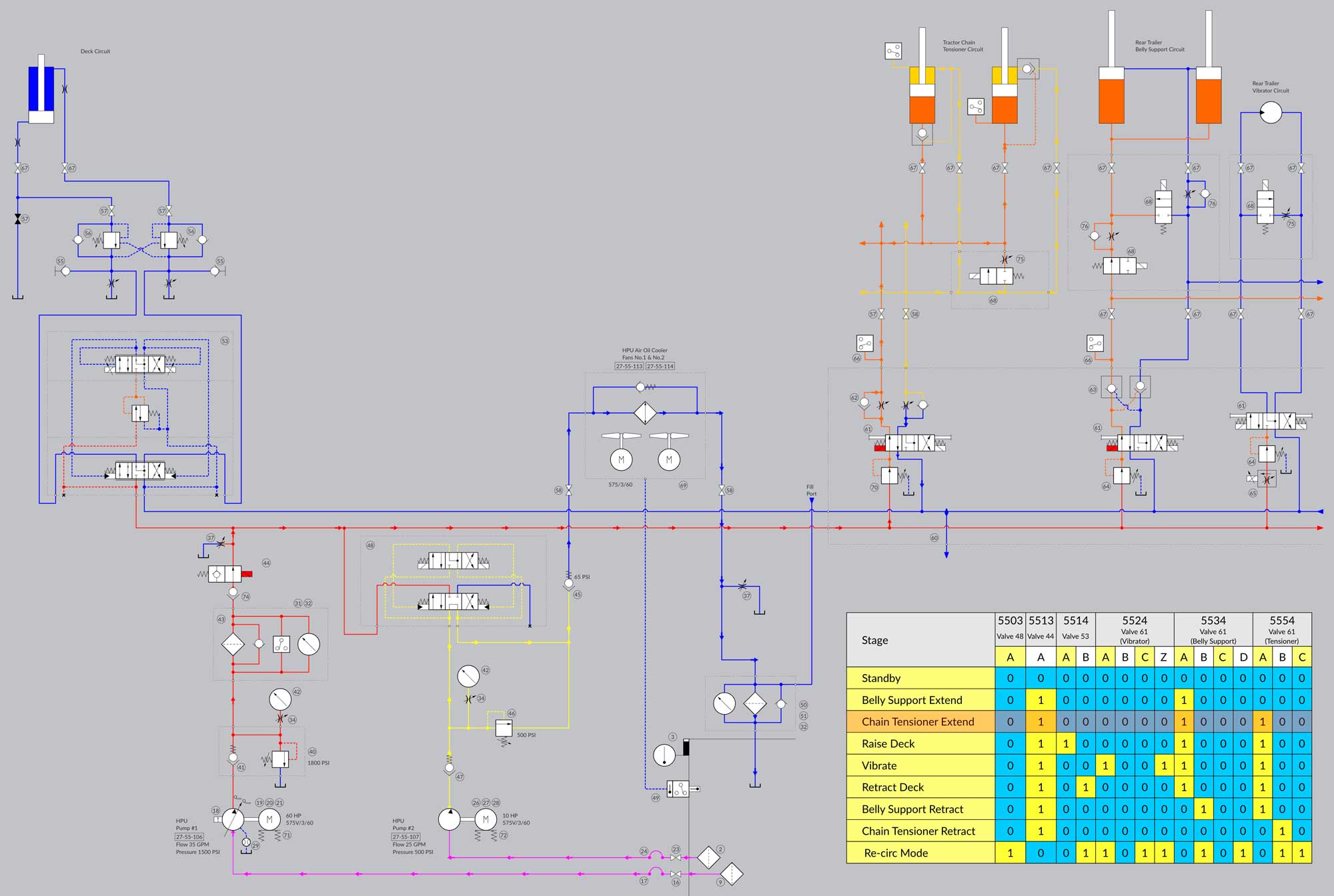

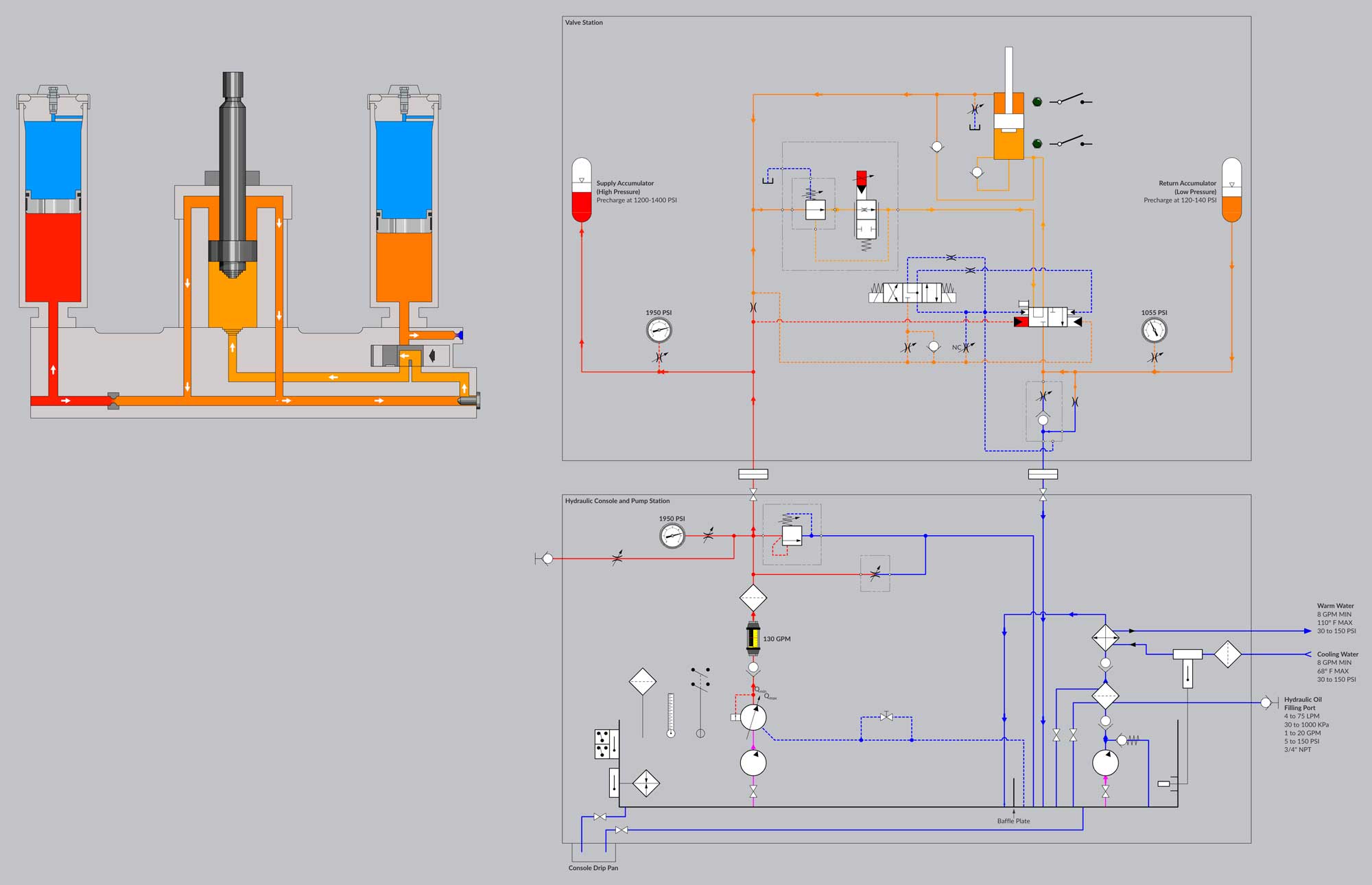

Pressure Diffuser

Objective: Interpret fast stroke, accumulator aided cylinder motion designs

Activity: Design accumulator tests and maintenance requirements

Verify required flow rates for each stage of machine cycle

Very informative. The pulp mill examples are very beneficial in understanding how systems and components function. This course is a "must take" for anyone dealing with hydraulics.Kurt W. ALPAC

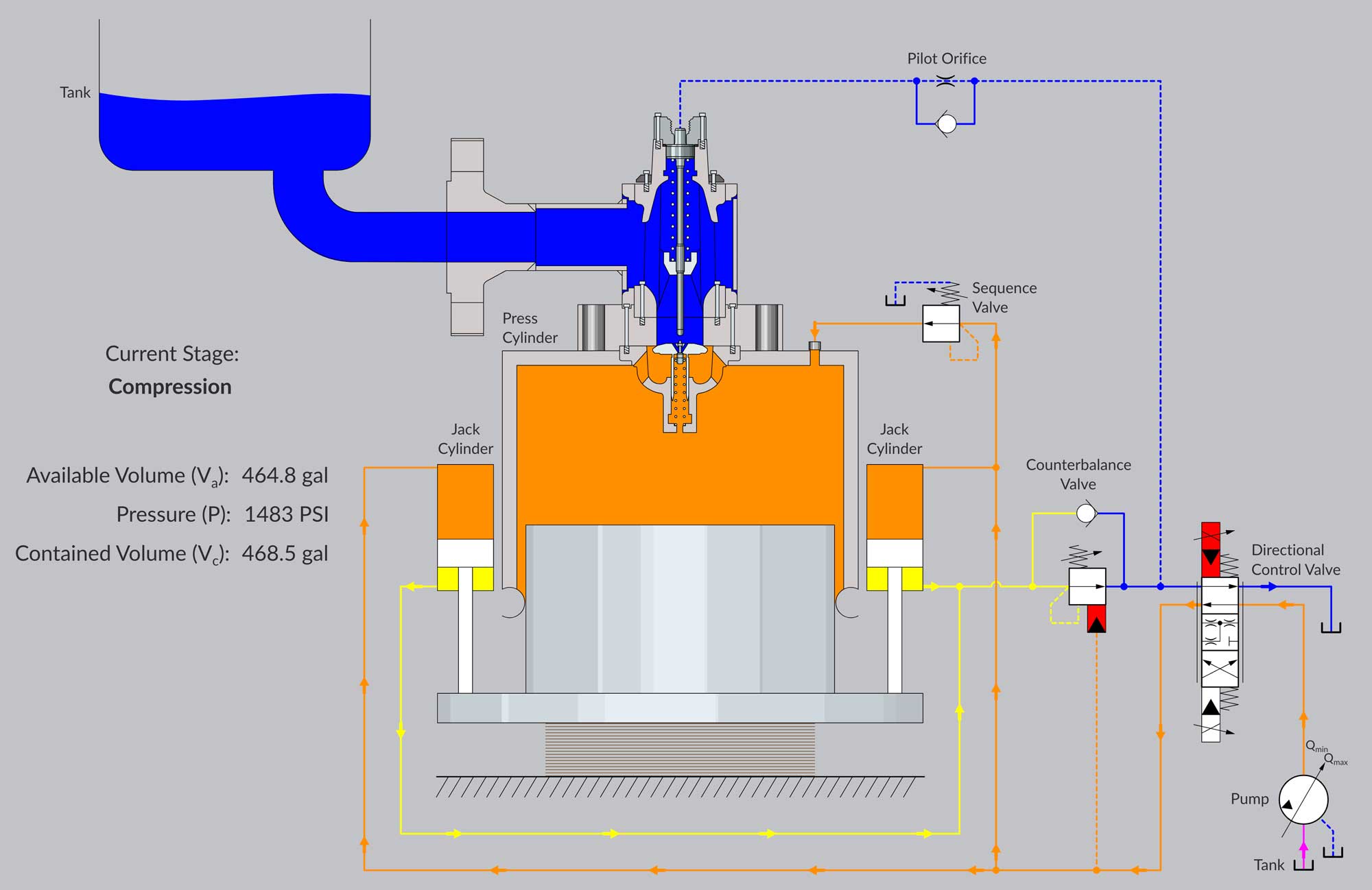

Bale Press

Objective: Verify pre-fill valve and jack cylinder based bale press functions

Activities: Identify test points for critical pressure tests

Adjust counterbalance, foot valve and decompression valves with confidence

Very Good. I like how he explained how the valves work, and then how they work on our equipment.Tyler O., Meadow Lake Mechanical Pulp

Proportional Valves

Objective: Explain proportional valve principles and make basic adjustments

Activity: Valve connection and tuning for gain, deadband, ramp and more

Learn about common electro-hydraulic fault issues!

Excellent teacher - great job, thanks. Very well thought out lessons and work exercises. Well worth taking from apprentices to highly seasoned journeymen.Glen D., ALPAC

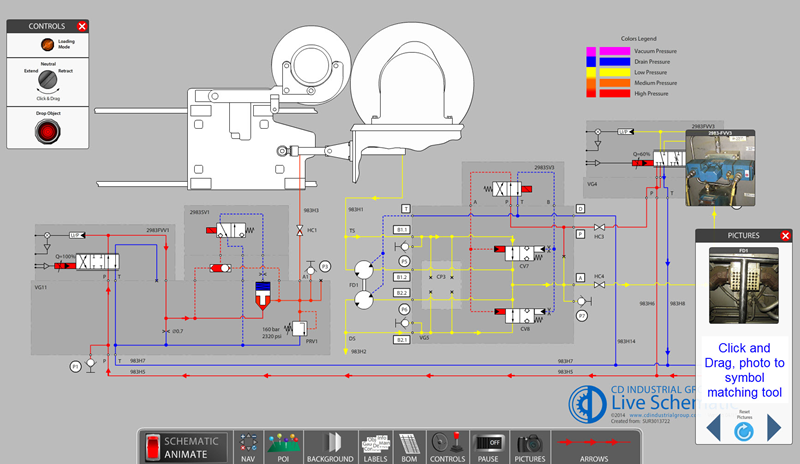

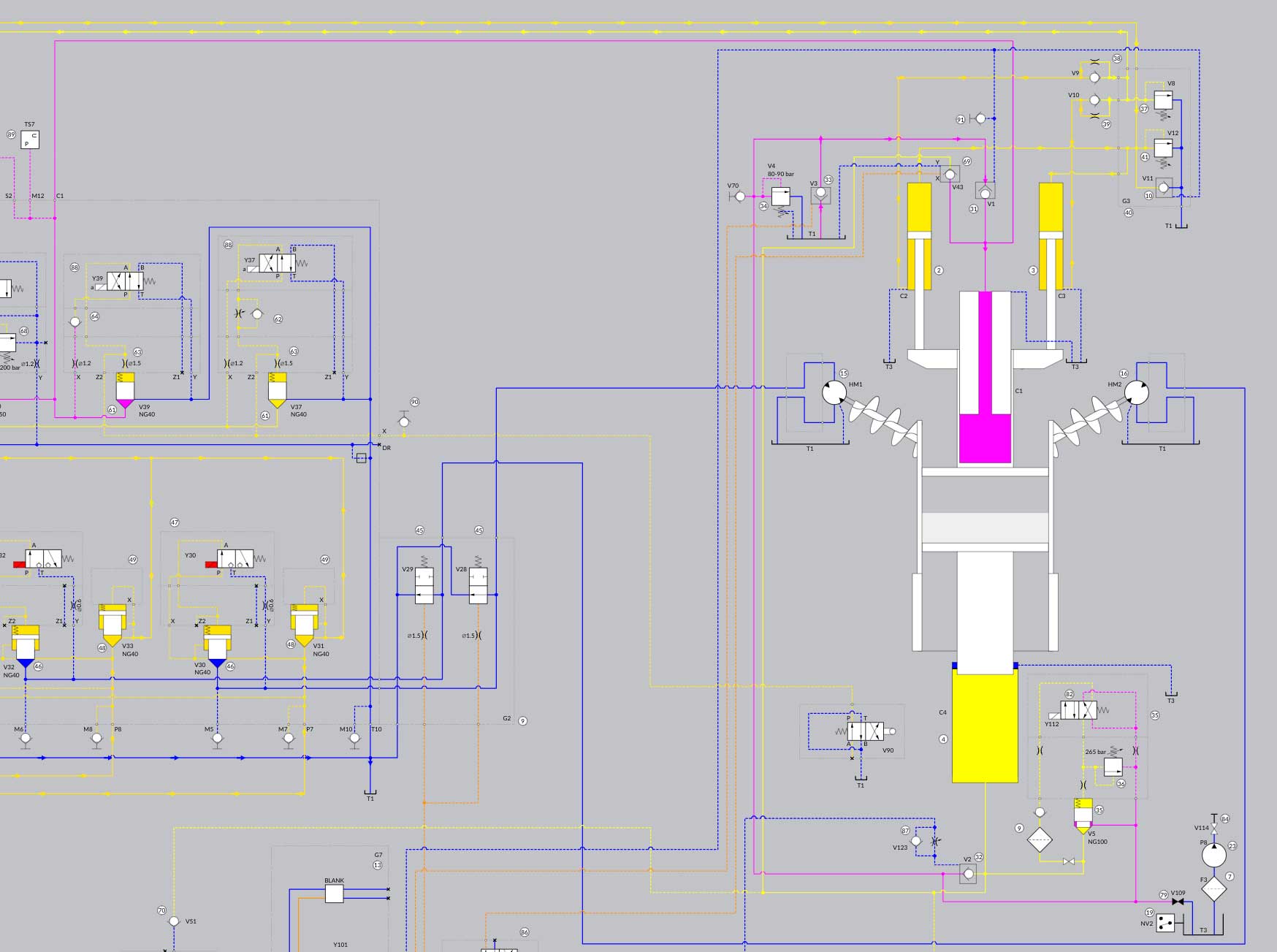

Slab Press

Objective: Interpret the complex multi-pump, multi-cartridge valve schematics

Activities: Confirm the sequence of valve activation for aid in troubleshooting

Verify parallel pump flow rates and cartridge valve malfunctions

The most valuable information I will use are the troubleshooting techniques as we commonly just replace parts when a problem is found.Stewart R., Norampac

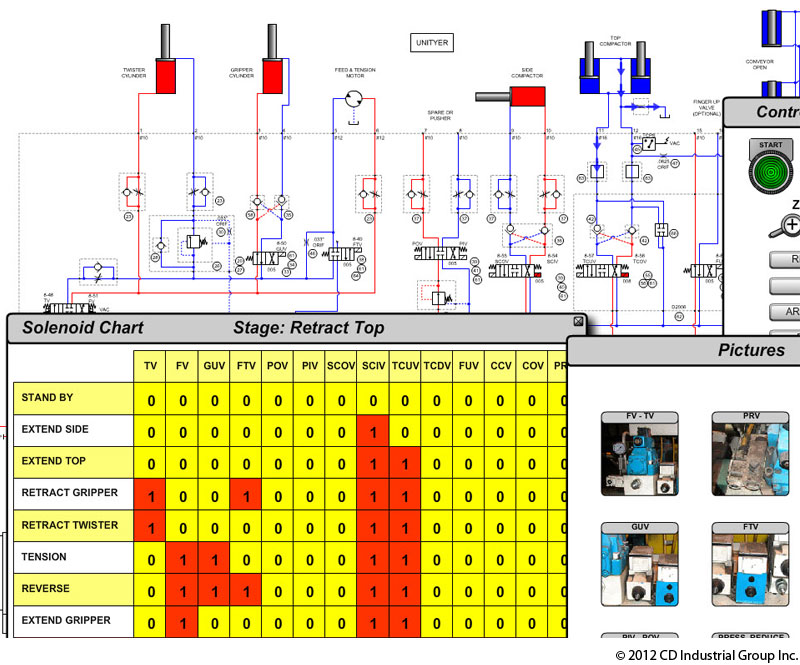

Unityer

Objective: Explain high speed packaging hydraulic systems

Activities: Diagnose and solve solenoid valve problems on unityer machines

Create your own solenoid charts to aid troubleshooting fast cycling systems

The troubleshooting approach has changed my approach to tackling a problem. I think you couldn't find a better instructor. Very impressive.Rob P. Abitibi