System Parameters

Objective: Review hydraulic principles and misconceptions that affect troubleshooters

Activity: Conduct a load (volumetric) test on a piston pump

Avoid troubleshooting guesswork by knowing the condition & properties of the fluid source - the pump!

"Excellent - good visual aids and hands-on. A must have course."James T., Teck

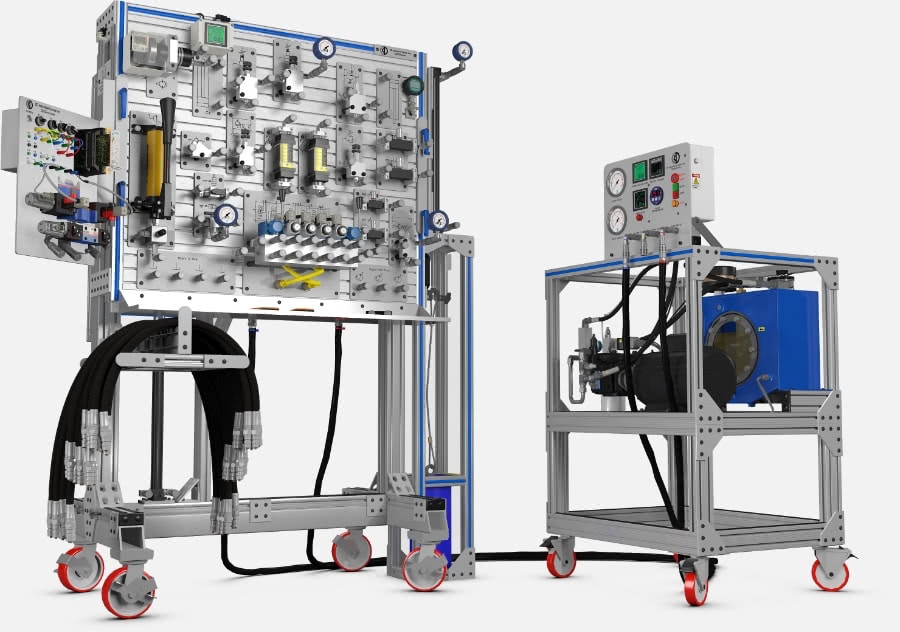

Systems Design

Objective: Analyze complex circuit designs

Activity: Design and connect circuits on our training panel to solve basic hydraulics problems

Learn to recognize groups of valves and designs within larger systems!

I understand the system and now I have the ability to troubleshoot the issue instead of just replacing parts.Jorge E., Pioneer

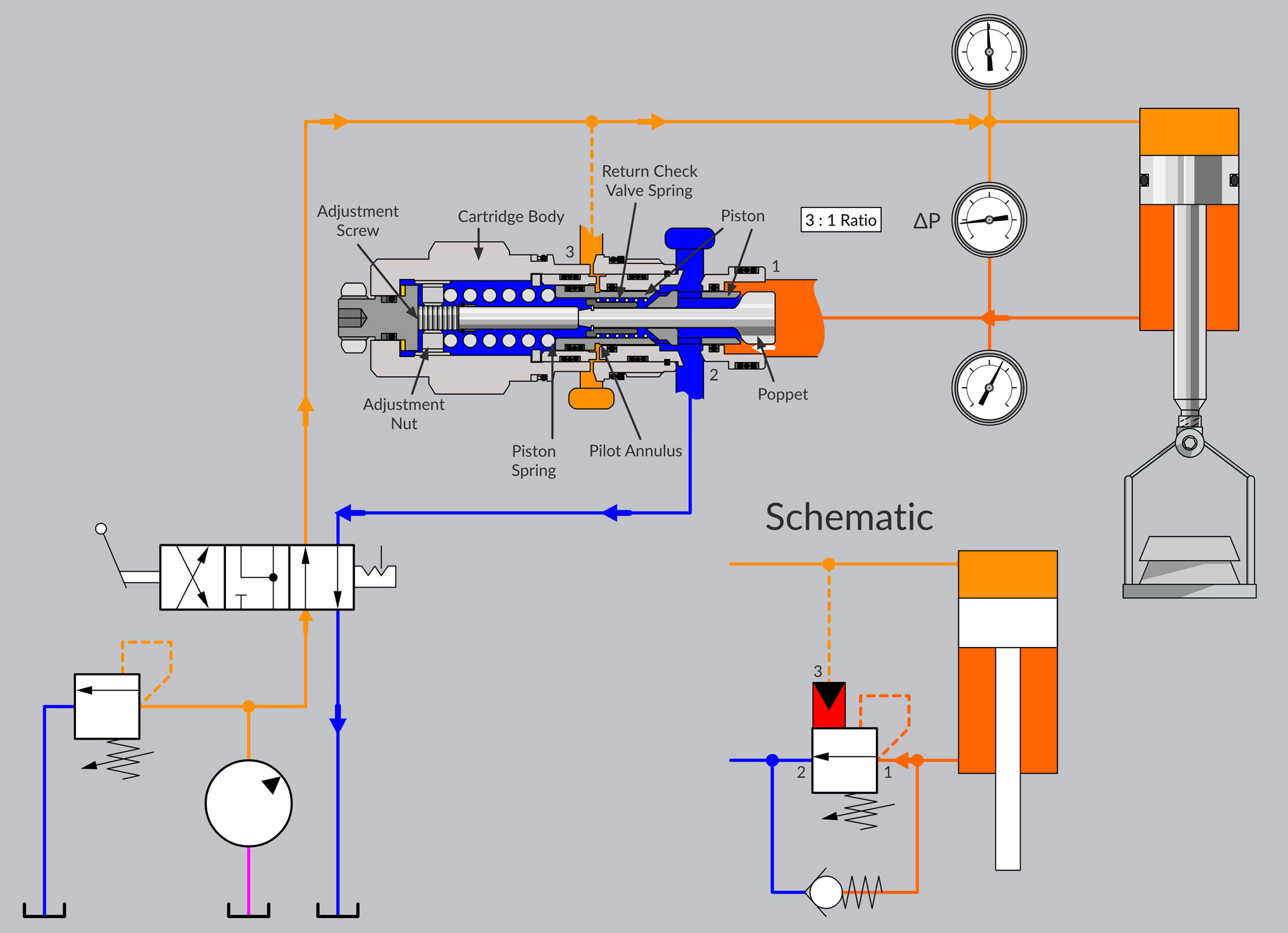

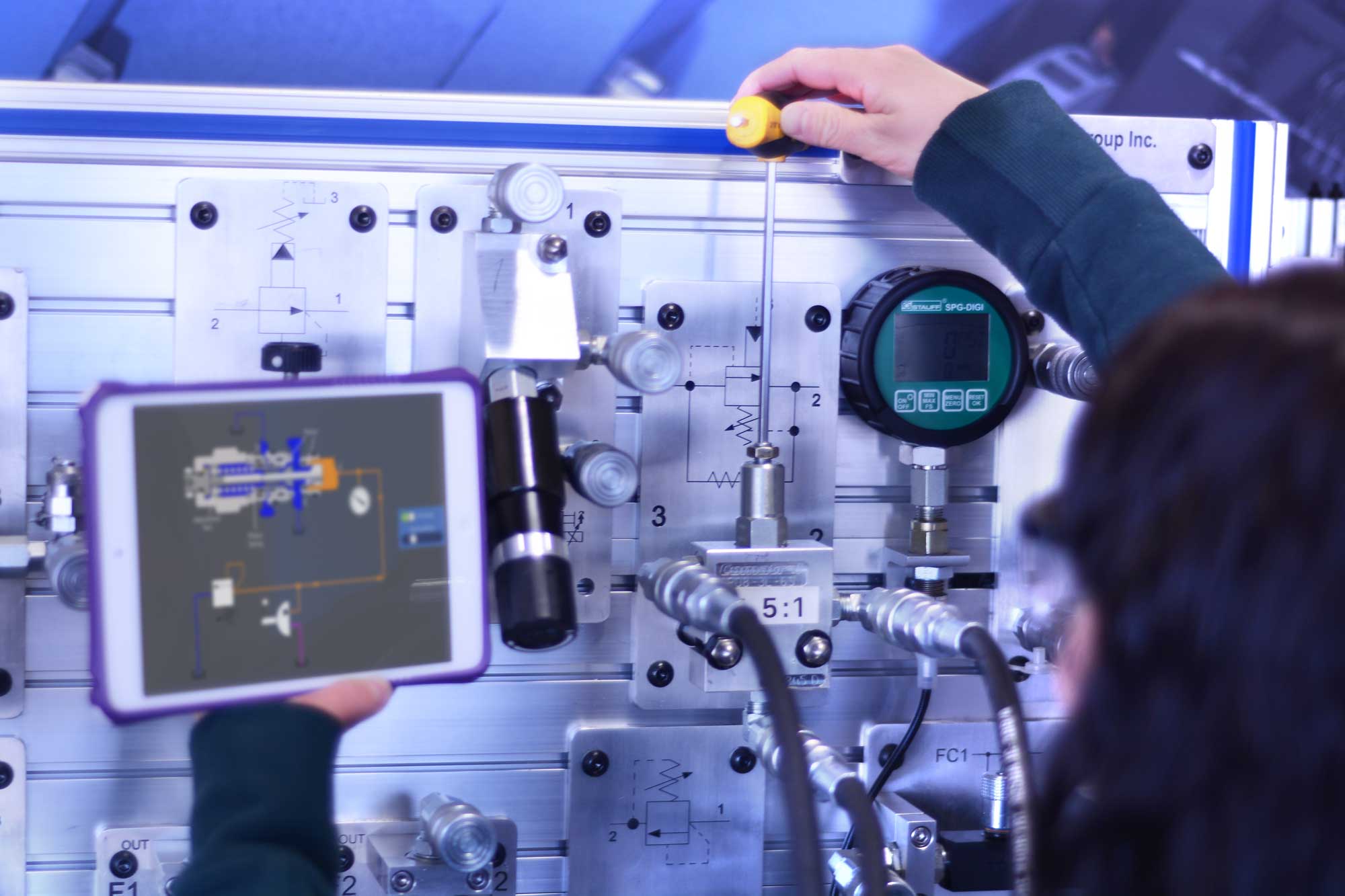

Safe Valve Adjustments

Objective: Set pressure valves using the correct, safe method

Activity: Adjust a counterbalance valve, safely, in simulation and on our training panel

A one quarter turn of a pressure valve adjustment can increase pressure by 500 psi!

"Very well structured - equal parts practical and theory. The panels are a lot of fun."Carl D., Westcoast Cylinders

Preventative Maintenance

Objective: Describe preventative maintenance procedures

Activity: Identify maintenance tasks and frequencies for given systems

Find out what it takes to get long life from your systems!

Good mix of industry standards, parts and using our equipment schematics as examples. Very good and useful, especially with animation.Gerald R., Ridley Terminals

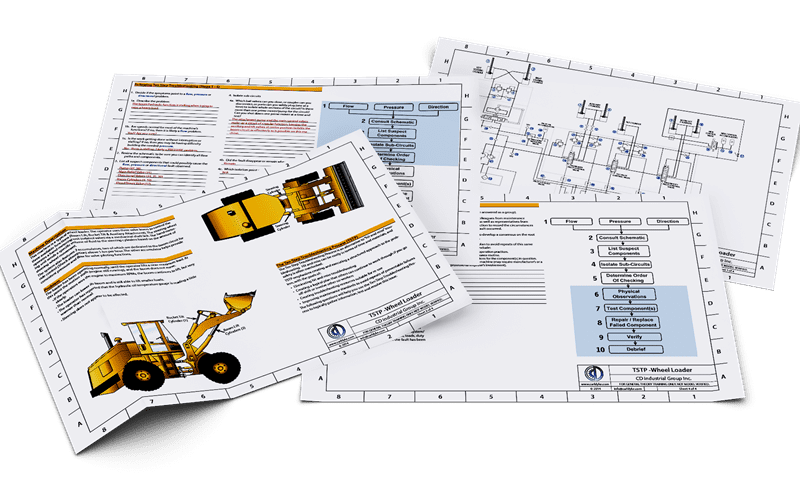

System Troubleshooting - Mobile

Objective: List the steps in logical troubleshooting

Activity: System troubleshooting simulation exercise

Learn the ten steps to logical and organized troubleshooting!

Course content was valuable to me because it was about equipment I actually work on daily,Brandon V., Pioneer

System Troubleshooting - Plant

Objective: List the steps in logical troubleshooting

Activity: System troubleshooting simulation exercise

Learn the ten steps to logical and organized troubleshooting!

Course content is excellent. All very useful and very applicable.Tom H. BC Hydro

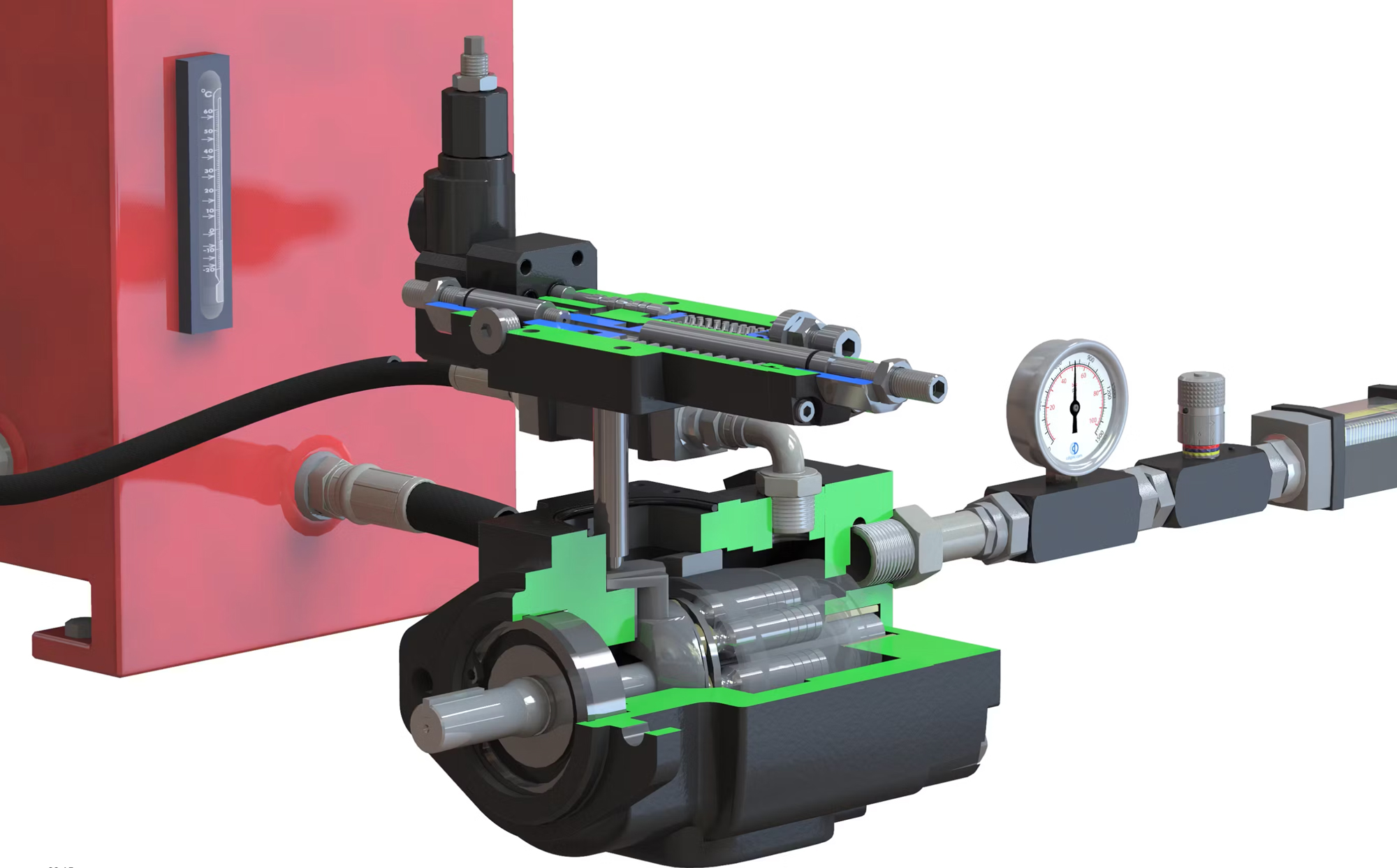

Hydraulic Pumps

Objective: Compare and explain the principles of various pump controllers

Activity: Work with our simulations and with pumps on our learning power units.

Know your inline and cross-axis pressure compensators.

Great content, the simulation were a great way to get a better understanding on how and what is actually going on internally.Cole B., Resolute Forest Products

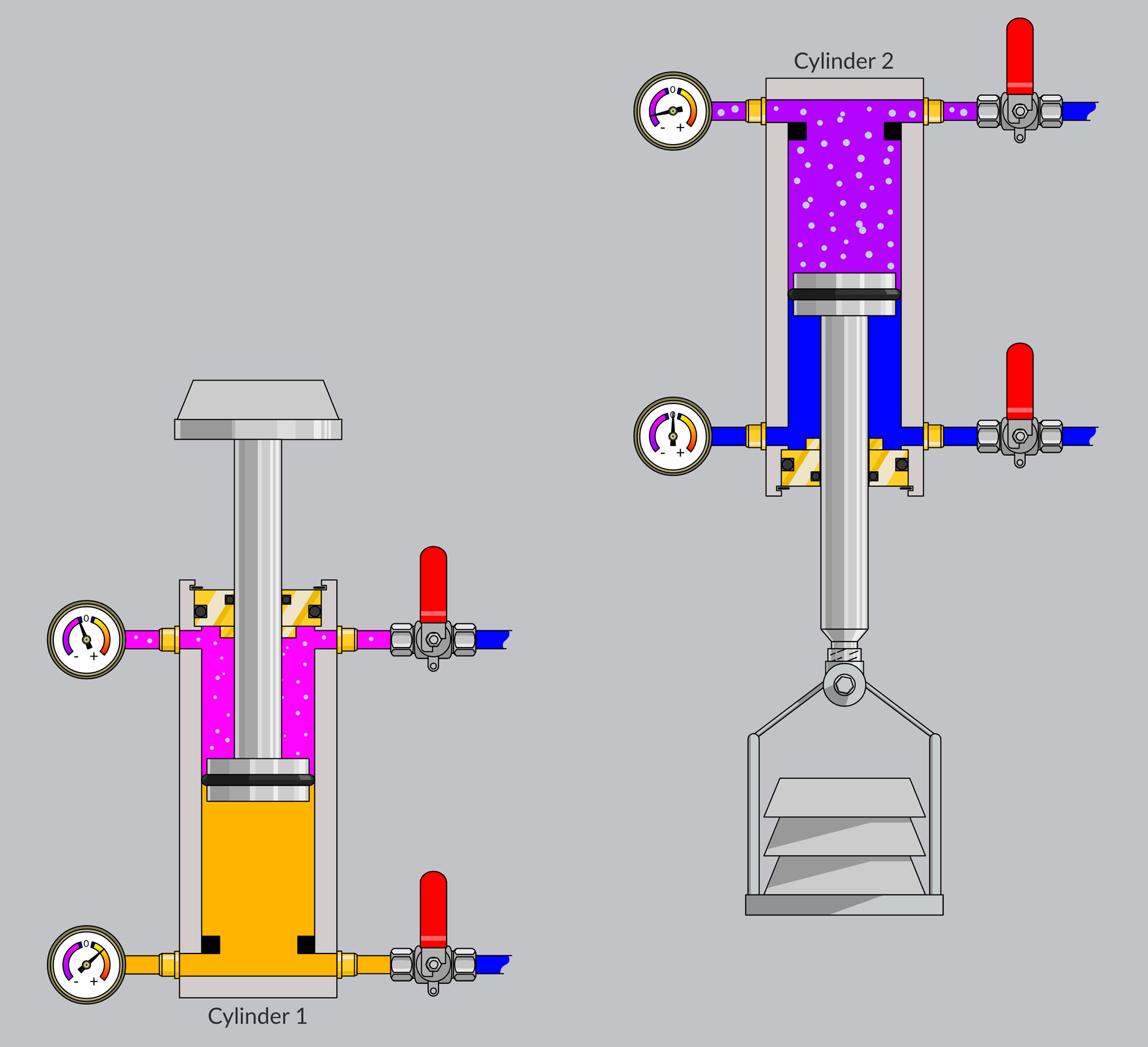

Actuators

Objective: List procedures to diagnose common problems in cylinders and motors

Activity: Work with an internal cylinder leakage simulation and with our cylinder bypass panel

Learn cylinder drift myths and secrets, and the steps to keep pressure intensification and cavitation under control!

I liked the graphic animation of hydraulic systems, makes it easier to visualize.Thomas G., BC Rapid Transit

Accumulators

Objective: Identify accumulator models, safety blocking valves and precharge connections

Activity: Safely maintain nitrogen precharge pressure

Test your systems knowledge with the Accumulator - Motor Challenge

Excellent. Goes beyond the "basics" of hydraulics, and gets you thinking about the system as a whole. Lawrence V., Fluid Power Solutions (MiMotion)

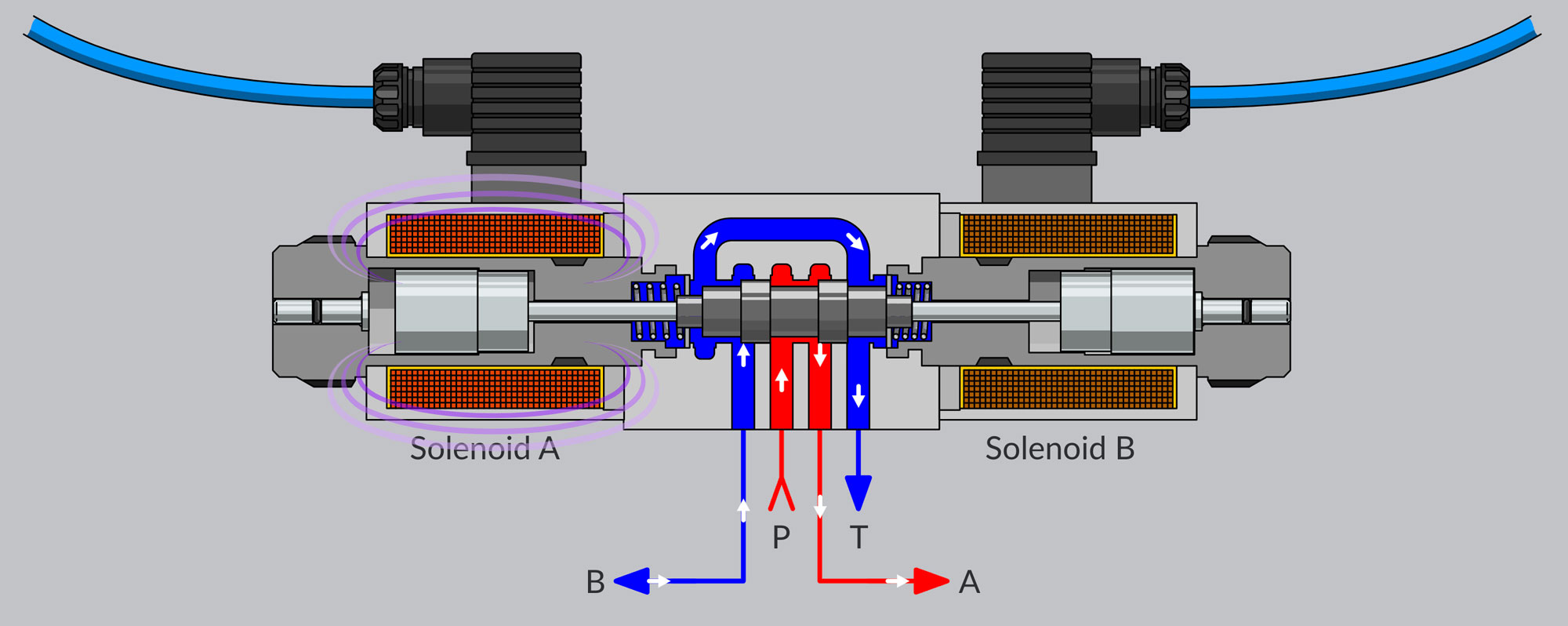

Valves

Objective: Identify valve designs and diagnose common problems.

Activity: Solenoid tests & valve disassembly, inspection and reassembly

Learn to make logical checks to determine a valve problem!

Simply excellent course. Awesome.Craig M., Tolko