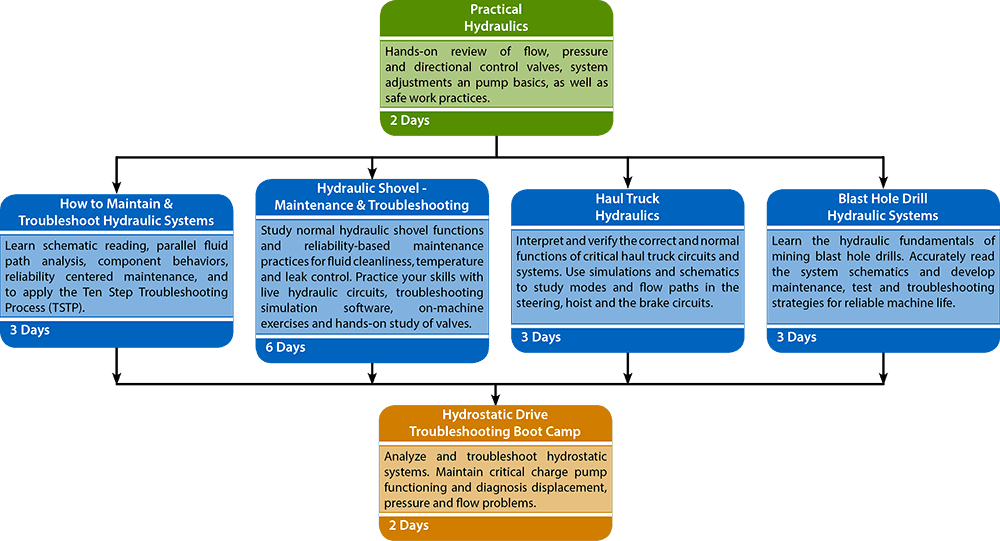

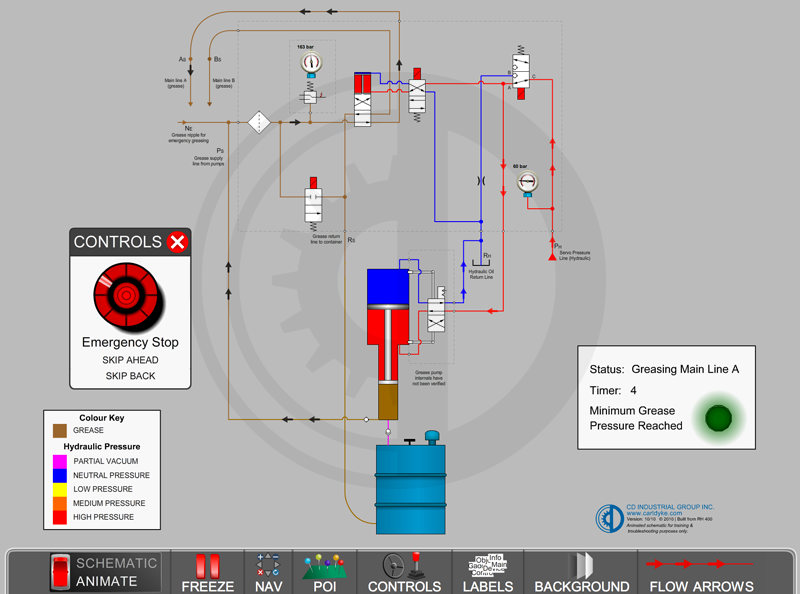

Greasing System

Objective: Explain the grease circuit functions and programmed cycles

Activities: Test for basic functions and performance in the greasing system

Learn the features of common grease pumps, injectors and distributors

Awesome course with computer animated schematics. To see oil flow gives a better understanding of components, valves and where they are located. The instructor took the time to show us to think through component troubleshooting.Charlie B., Syncrude

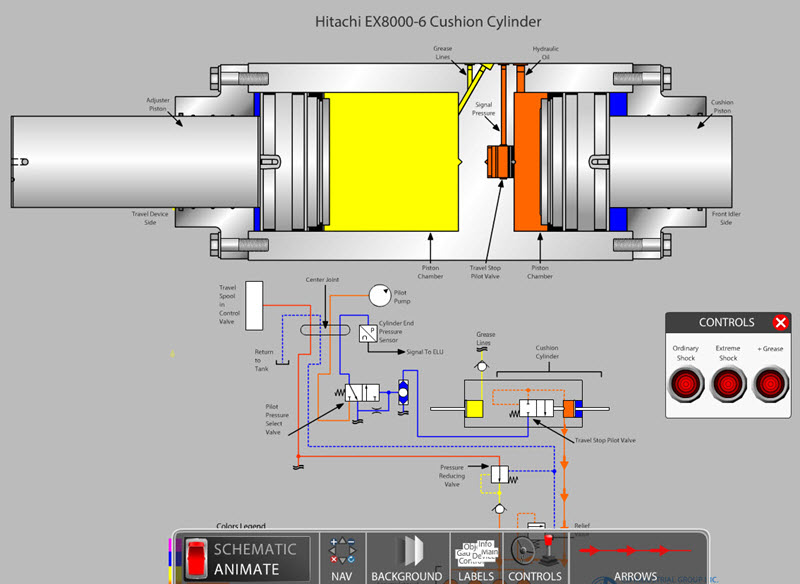

Track Tension and Cushion

Objective: Describe the track tension and cushion cylinder circuit

Activities: Identify hydraulic flow paths for ordinary and extreme shock

Learn to detect depleted accumulators and relief valves stuck open

The most useful for me was learning to read and use schematics to solve problems faster and more efficiently. The course content was great, covered a lot in five days.Dan K., Shell

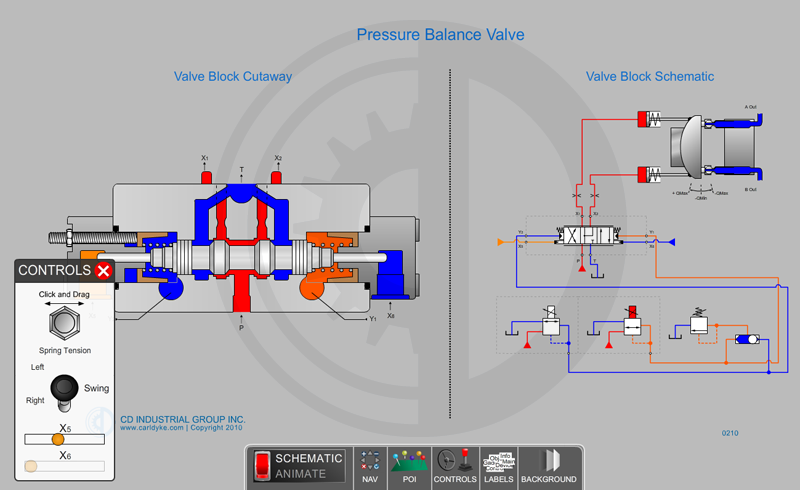

Pilot Circuit

Objective: Identify the components and functions of the servo and pilot circuits

Activities: Test pressure controls and electro-hydraulic proportional valves

Solidify your knowledge of pump piloting with pressure reducing valves

It is a very unique and interpretive way of teaching, very effective for myself.Devin Z., Syncrude

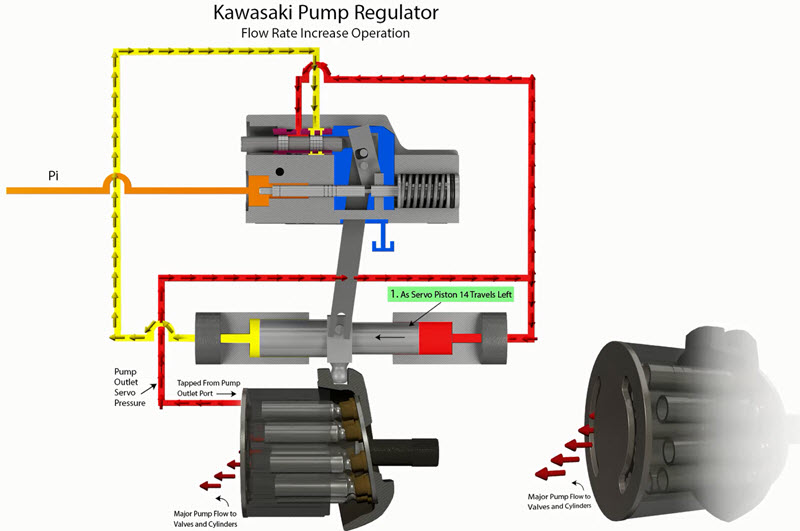

Pump Regulator

Objective: Describe the functions of the pump regulator

Activities: Identify specific pilot ports and pilot actions

Use our 3D sequences to learn your Kawasaki pump regulator functions cold!

Very well done. The animated circuits make it very easy to understand. A lot of information in five days, but this course teaches better than trade school ever did.Jeff M., Shell

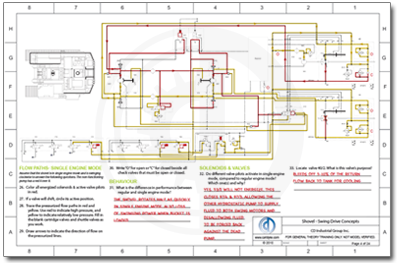

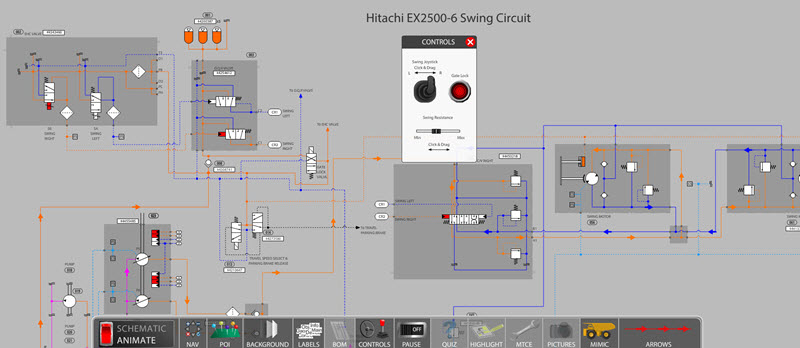

Open Loop Swing Drive

Objective: Interpret open-loop swing systems

Activity: Test for correct electrical pilot signals and pilot pressures

Know your EHC and DQR and port relief valve functions

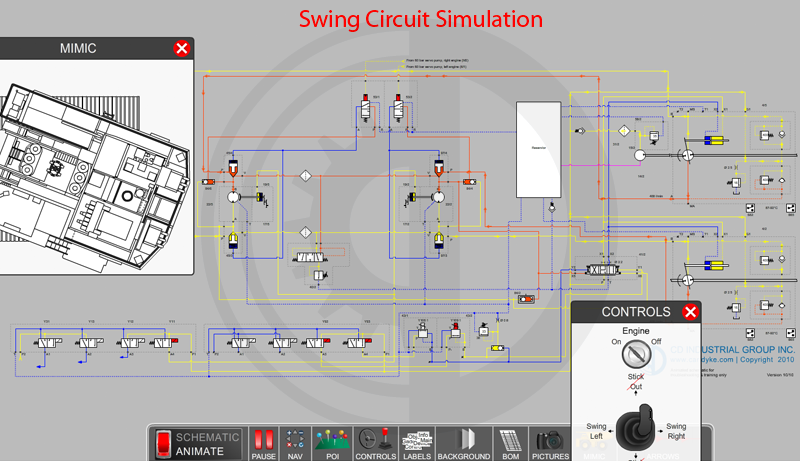

Closed Loop Swing Drive

Objective: Interpret closed-loop swing systems

Activity: Test for correct servo, charge pressure and flushing functions

Know your over-running mass controls and single engine modes

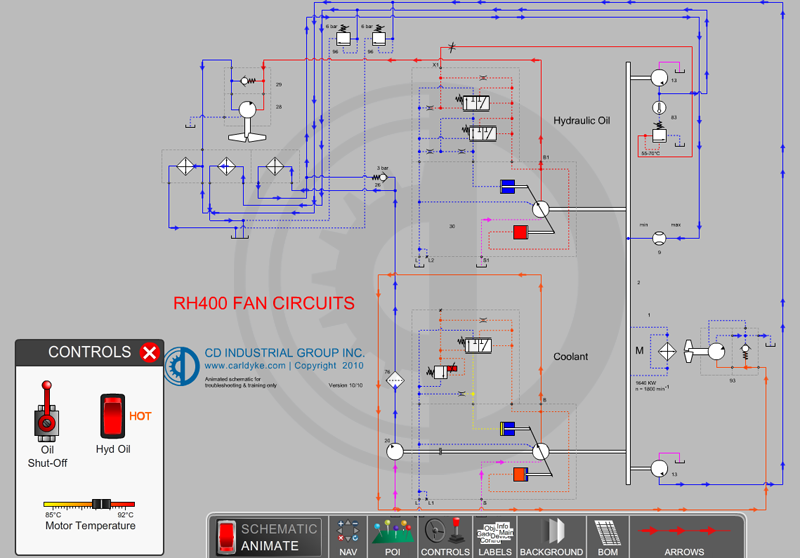

Cooling Fan Drive Circuit

Objective: Verify correct thermal valve triggering of cooling circuits

Activities: Adjust pump controls and valving to achieve correct fan speed

Work with the flywheel effect of large diameter fans

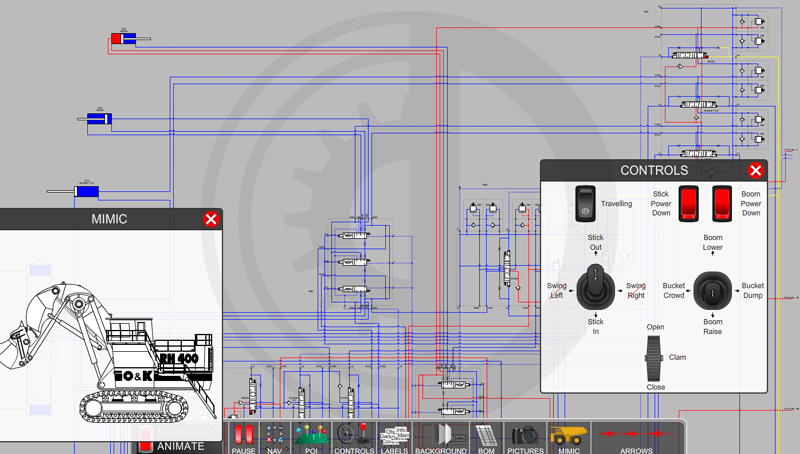

Attachment Circuit

Objective: Interpret attachment pilot and directional valve schematics

Activities: Learn to test for load holding check valve and float problems

Confirm the role of port relief and anti-cavitation valves

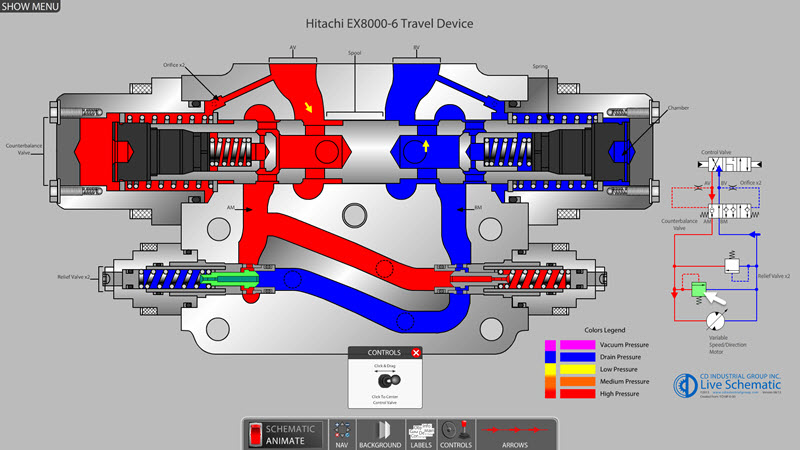

Travel Valve

Objective: Describe the functions of the travel valve

Activities: Identify counterbalance and port relief functions

Detect cross-port relief valves stuck open

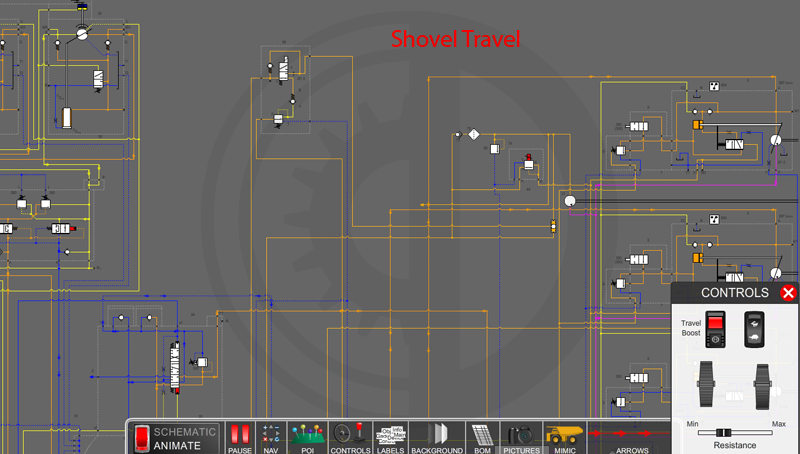

Undercarriage Travel - Propel Circuit

Objective: Explain propel circuit paths and functions

Activities: Diagnose and solve motor and counterbalance problems.

Learn how the pump management system limits engine torque requirement