The instructor had good communication skills, good knowledge of hydraulic systems and was able to explain things so that they are easily understandable to everyone. The course lets you better understand schematic drawings and the numerous troubleshooting points throughout the system.Darin Z., West Fraser

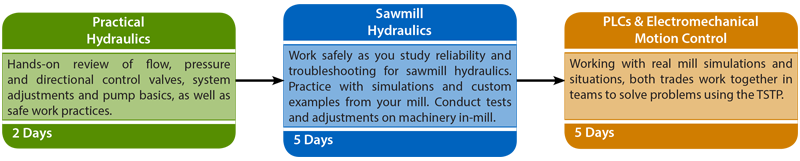

Starting with Simple Systems Analysis

Objective: Learn to check the easy-to-check items first, such as the tank breather

Activity: Diagnose problems with the chip bin hydraulics

Basic maintenance checks and simple troubleshooting comes first!

The hands on look at hydraulic pumps, valves etc., was extremely helpful. Carl is very knowledgeable and informative – interesting and animated.Chris K., Tolko

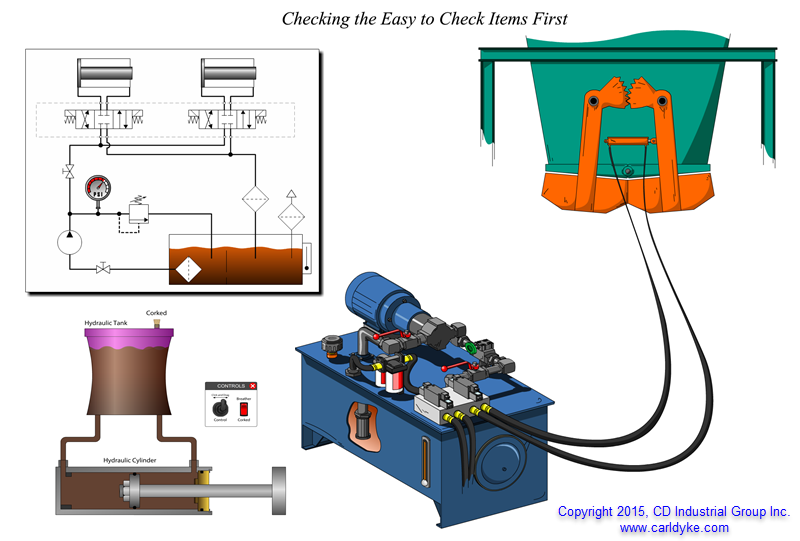

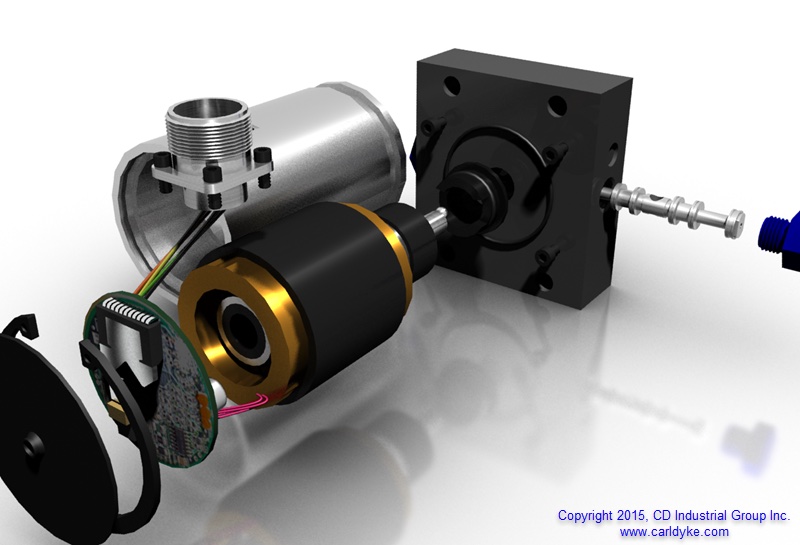

Woodward Textron Servo Valves

Objective: Describe the inner workings of rotary direct drive servo valves

Activity: Disassemble a rotary direct drive servo valve

Get inside expensive valves via 3D and cutaway disassembly!

Excellent presentation with computer simulations that back up the instructor's extensive knowledge and experience. I highly recommend this course to othersCharles W., Tolko

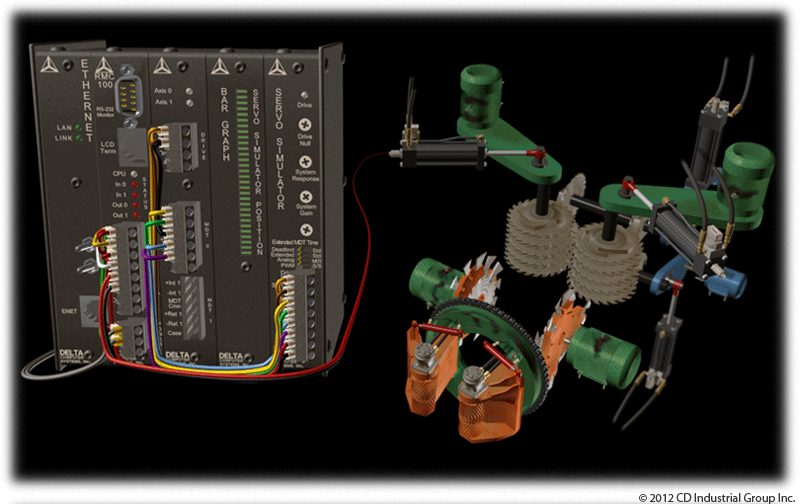

Servo Valve Basics

Objective: Connect and operate servo and proportional valves on our training panel

Activity: Interpret catalogue data and operational specifications

Learn to adjust and care for fighter jet quality Moog servo valves!

Made hydraulics hands-on and understandable. They are the best – hire them for a course or two and then you'll know what I mean.Wayne C., Interfor

Servo Valve Training Hands-on

Objective: Test servo valve performance

Activities: Mechanically and electronically adjust servo valve parameters

Diagnose servo valve problems

The instructor knows his stuff and has a lot of information on every type of hydraulics. The course has opened my eyes towards understanding the different types of hydraulic systems.Jeff B., West Fraser

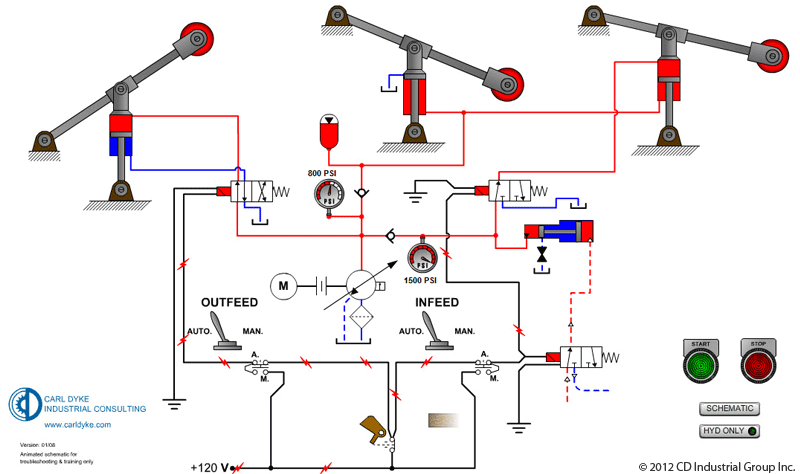

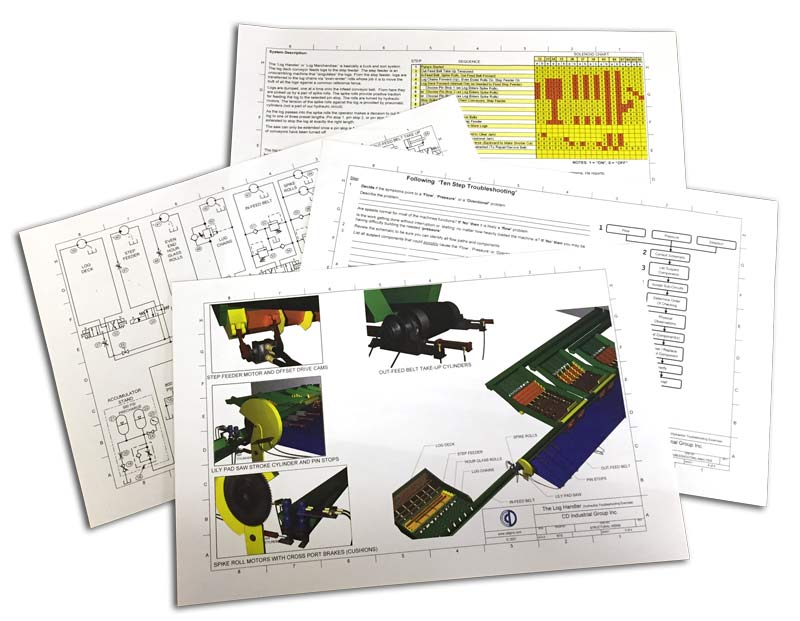

Log Infeed and Merchandising

Objective: Explain typical hydraulic systems on log infeed machines

Activities: Create schematic based diagnostic tools

Know your step feeder, singulator, log sweeps and spike roll systems

It was the best hydraulics course I've ever taken!Leo H., Tolko

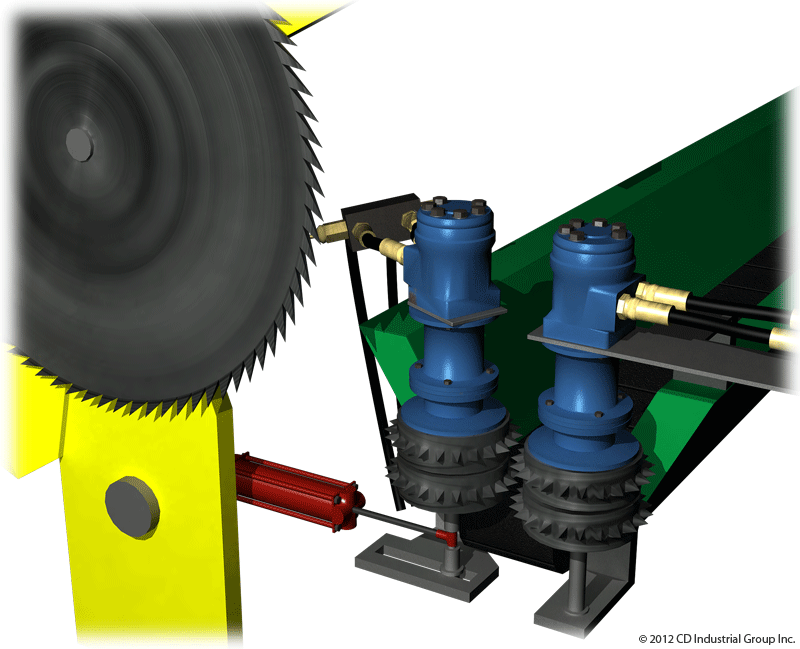

Setworks and Cutter Positioning

Objective: Identify the components of servo cylinders and multi-axis systems

Activities: Test for correct pump pump flows to support multiple flow paths

Solidify your skills with closed loop motion control

Mark was very pleasant and taught to each individual's needs and specific applications. At the end of the first day, he was very interested in seeing all of the hydraulic systems at my site. He then brought up examples from those systems on day two.Terry D., West Fraser

Stackers and Tilt Hoists

Objective: Identify the key features of hydraulic stackers and hoists

Activities: Test unloader and counterbalance valves

Know your regenerative circuit functions

The instructor took the time to instruct so that things were understood.Jim C., Canfor

Feed Rolls

Objective: Interpret fast stroke, accumulator aided cylinder motion designs

Activity: Safely test air to oil pressure intensifiers

Flow test for correct rates at each stage of machine cycle

Excellent instructor. Great course to take. I would recommend it to others.Jeff F., West Fraser

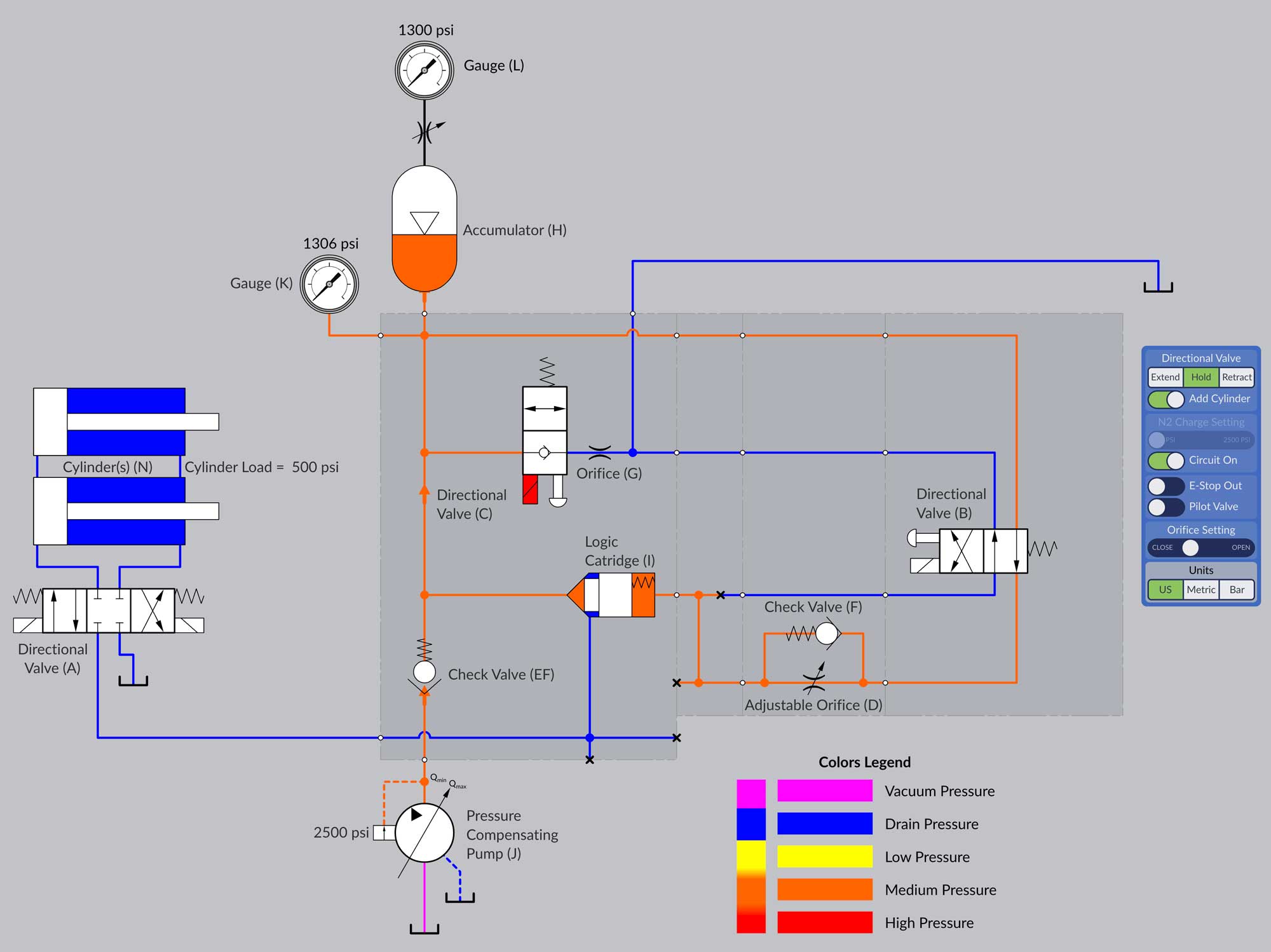

Accumulator Controls

Objective: List accumulator functions and design applications

Activities: Verify correct accumulator precharge pressure and proper functioning of safety blocking/bleed valve

Repair accumulators like a pro

I learned what each component does, and what it might do as it fails. The course was quite useful. Familiar components were better understood through your simulations.Ken L., Interfor

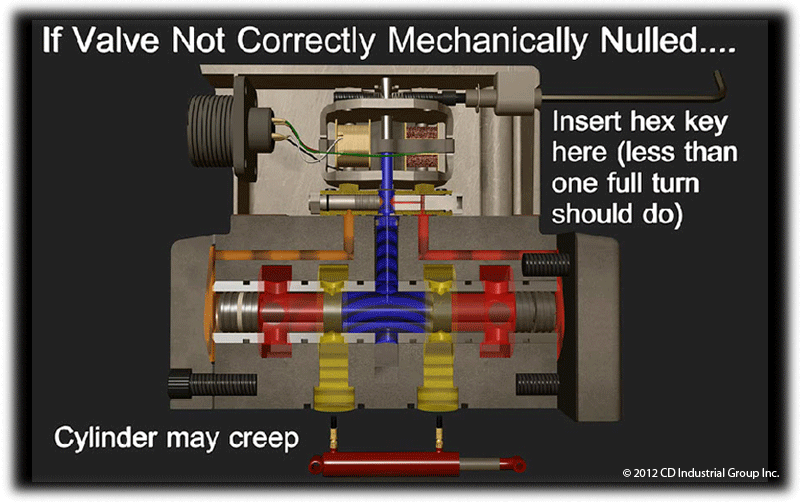

Servo Valve Training

Objective: Explain servo valve principles

Activities: Conduct electrical and mechanical valve nulling procedures

Know your Moog, Textron and Bosch servos

I learned the importance of having good preventative maintenance around hydraulic systems. A very reasonable learning pace for a diverse group. You took the time to use our prints to make the course very meaningful. Excellent!Kurt G., Weyerhaeuser

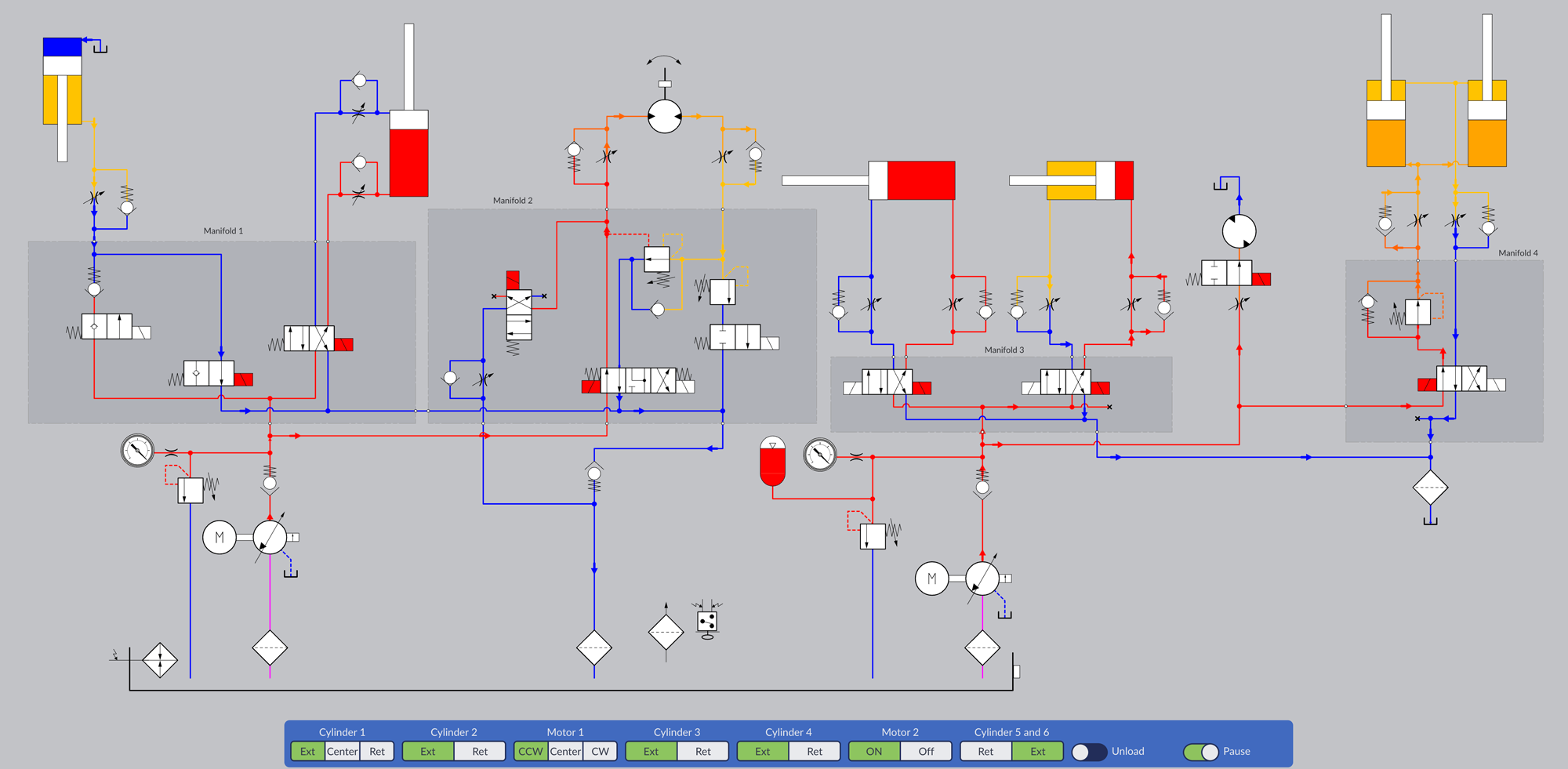

System Troubleshooting

Objective: List the steps in logical troubleshooting

Activity: System troubleshooting simulation exercise

Learn the ten steps to logical and organized troubleshooting!

The course content was great. The instructor covered a lot of different aspects of a hydraulic systems and how each component acts on it.Jim C., Weyerhaeuser