Alignment Theory Review

Objective: Describe consequences of shaft misalignment

Know your types of misalignment and their impact on machine reliability

Laser Alignment Principles

Objective: Explain the principles of laser alignment

Differentiate between emitters, prisms, and detector/receivers, and learn their respective advantages

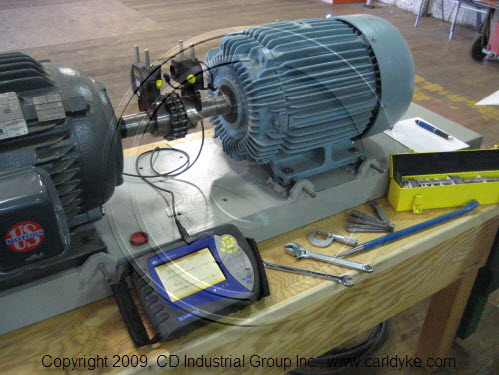

Laser Alignment Techniques

Objective: Demonstrate correct laser shaft alignment routines

Activity: Complete at least two computer simulation and two hands-on based laser alignment jobs

Mount, calibrate, and utilize lasers and their controller menus like a pro