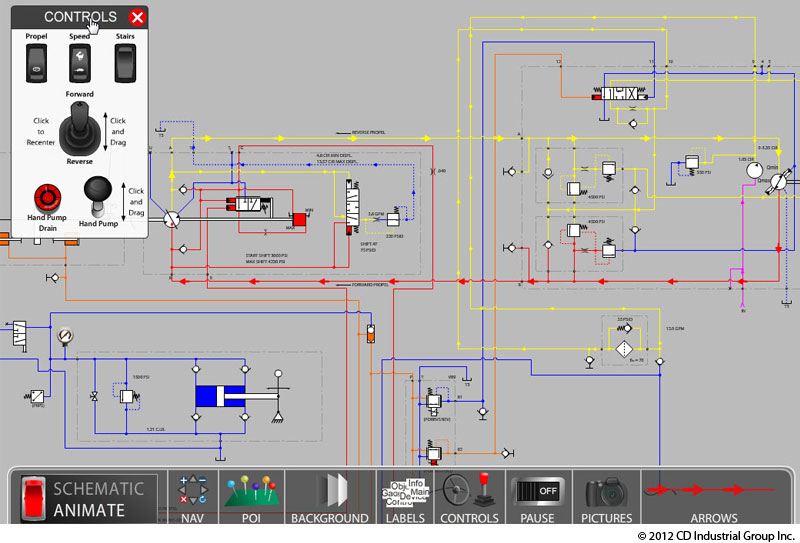

Travel Circuitry

Objective: Explain the functions of a closed loop propel system

Activities: Diagnose typical hydrostatic system problems

Know the undercarriage hydraulic functions cold

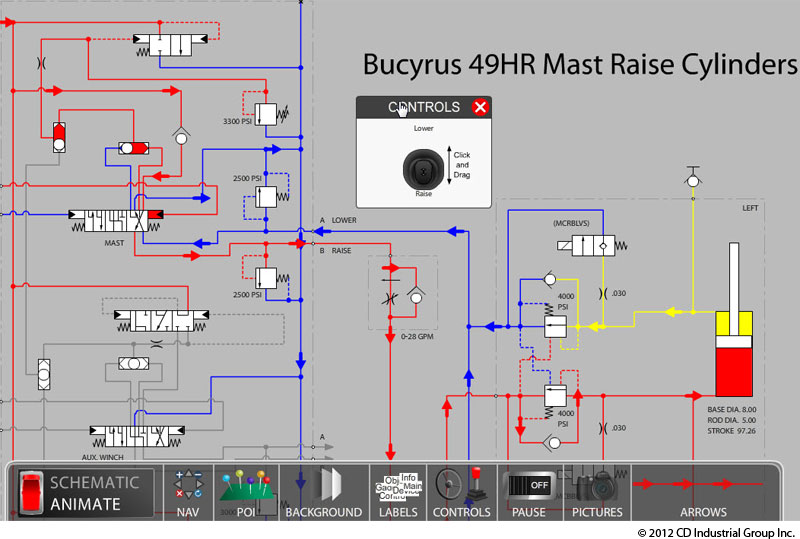

Mast Raise and Lower Functions

Objective: Identify the components of the mast raising circuits

Activities: Test valve piloting functions and port relief settings

Solidify your skills with counterbalance valves

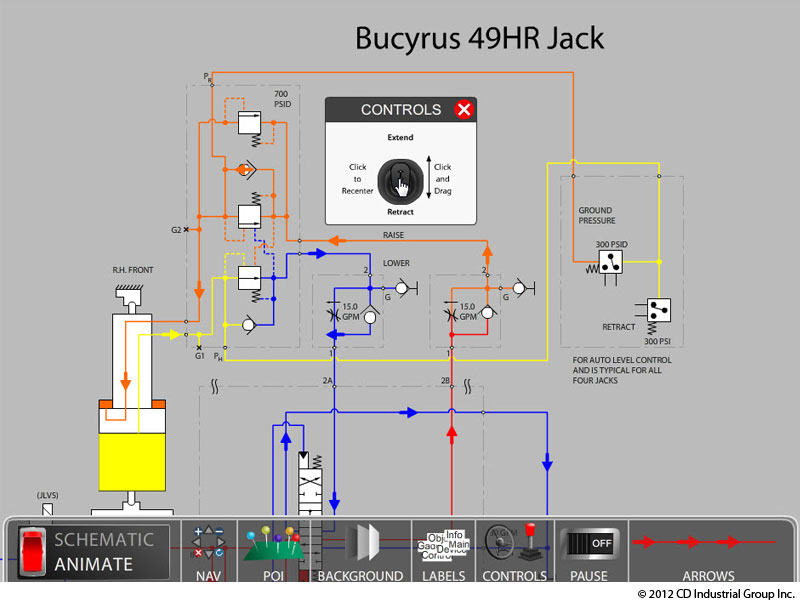

Jack Cylinder Circuits

Objective: Identify the components and their functions in the jack cylinder circuits

Activities: Diagnose auto-level malfunctions

Decode the mysteries of pressure compensated flow controls

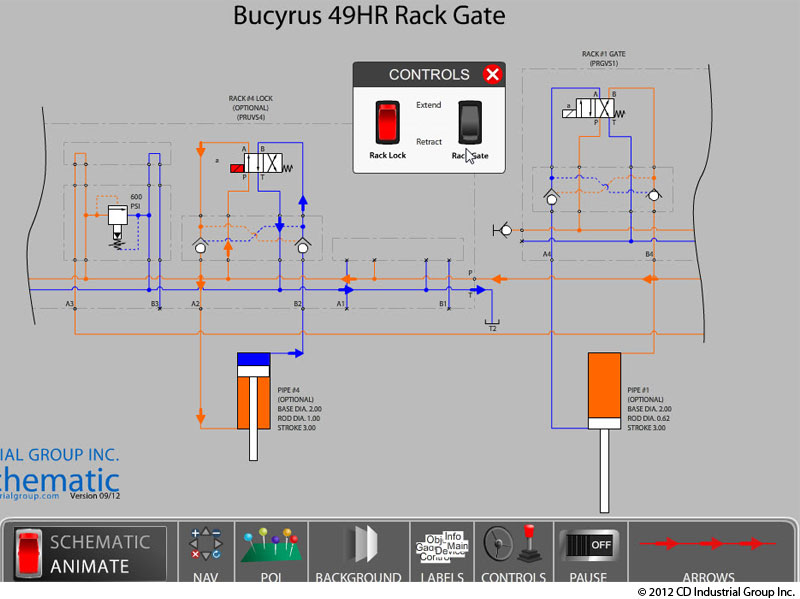

Pipe Rack Position Cylinders

Objective: Describe functions of components on the pipe rack position circuits

Activities: Test counterbalance settings and confirm valve pilot pressures

Know the six-port, two-position selector valves cold

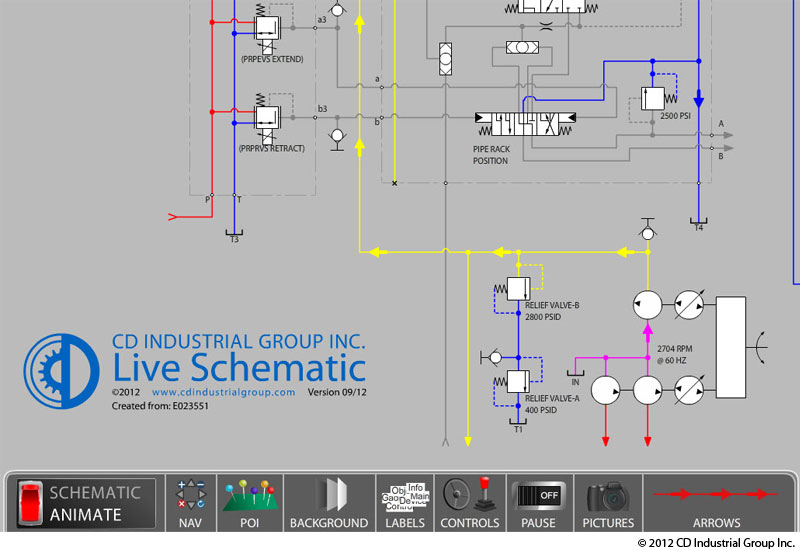

The Hydraulic Power Unit

Objective: Identify pump types and system pressure relief and unloading valves

Activities: Design pump volumetric and load tests to aid in troubleshooting

Know the key maintenance principles for long pump life

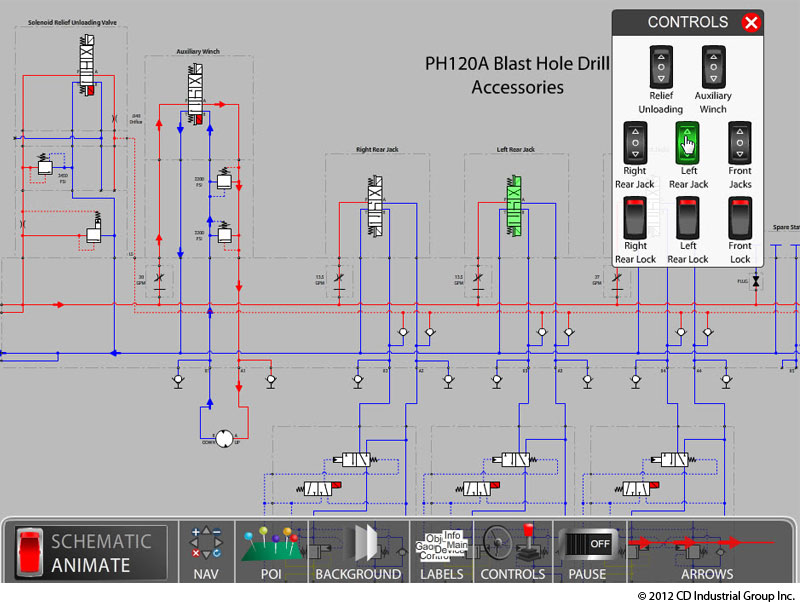

Auxiliary and Accessory Systems

Objective: Interpret auxiliary systems and circuit designs

Activity: Identify schematic paths for auxiliary winch, pin locks, dust seals and dust curtains

Know your grease and lube systems cold