CONTROLLOGIX HARDWARE

Objective: Describe common ControlLogix hardware configurations

Activity: Configure a chassis with processor and digital I/O cards

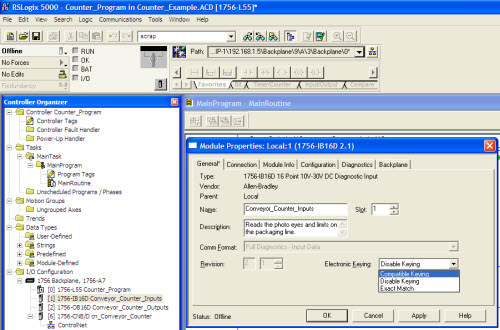

Keying a specific model of input or output card to a specific slot is done in the software

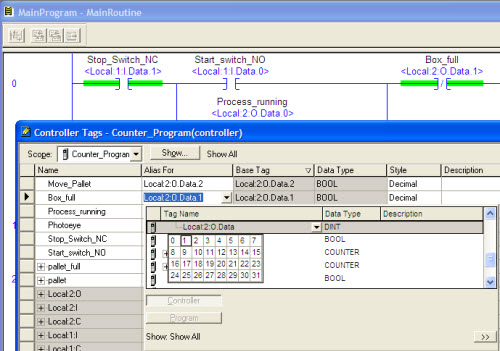

PLC PROGRAMMING

Objective: Demonstrate how to construct control programs

Activity: Create projects and tags. Insert instructions and verify your project

Downloading a project file to the PLC and monitoring your tags is easy to learn

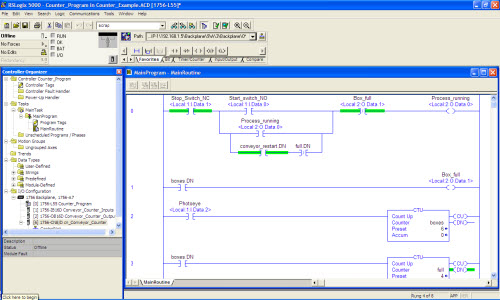

LOGIC INSTRUCTIONS

Objective: Explain and modify ladder instructions

Activity: Modify timers and counters, add new input, output and other bit level instructions. Work with word compares as well as compute and math instructions. Modify the light show program.

Basic logic is very powerful and easy to learn

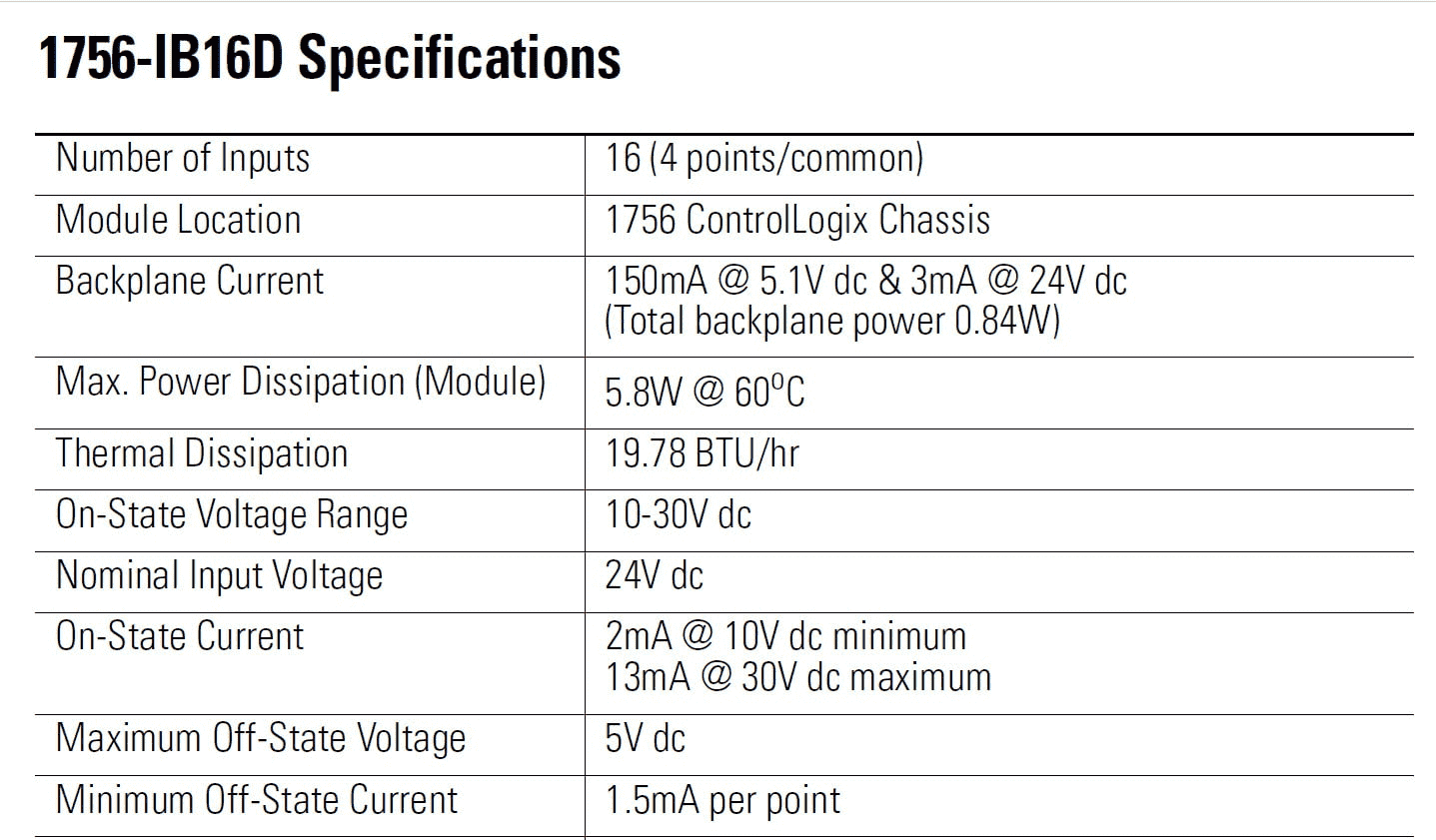

I/O MODULES & FIELD DEVICE CONNECTIONS

Objective: Demonstrate how to connect various I/O field devices to the PLC

Activity: Configure a variety of digital I/O modules and correctly hardwire field test devices such as proximity switches, relays, etc.

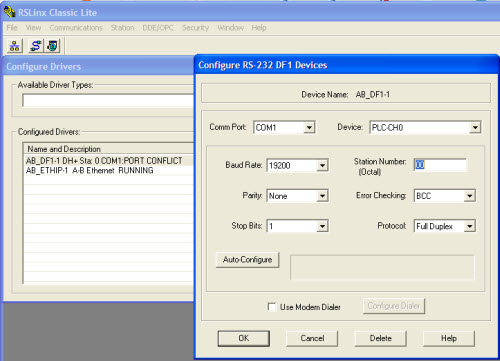

PLC COMMUNICATIONS

Objective: List steps to configure serial and ethernet communications drivers

Activity: Establish communications with PLC and download programs

Work proficiently with RSLinx and set the project file path

PLC TROUBLESHOOTING

Objective: Isolate and solve system faults

Activity: Use trend and data monitoring tools to analyze problems

Find out how to use troubleshooting tools that are built right into the PLCs software