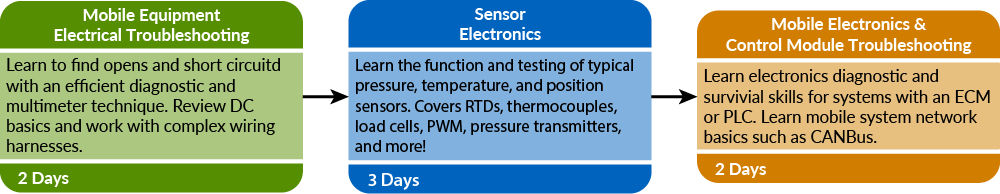

Electronics Troubleshooting Review

Objective: Lists steps and procedures for basic measurement and fault finding

Activities: Measure frequency and duty cycle of Caterpillar throttle position sensors and other PWM sensors

Review your basic fault finding and make meter measurements

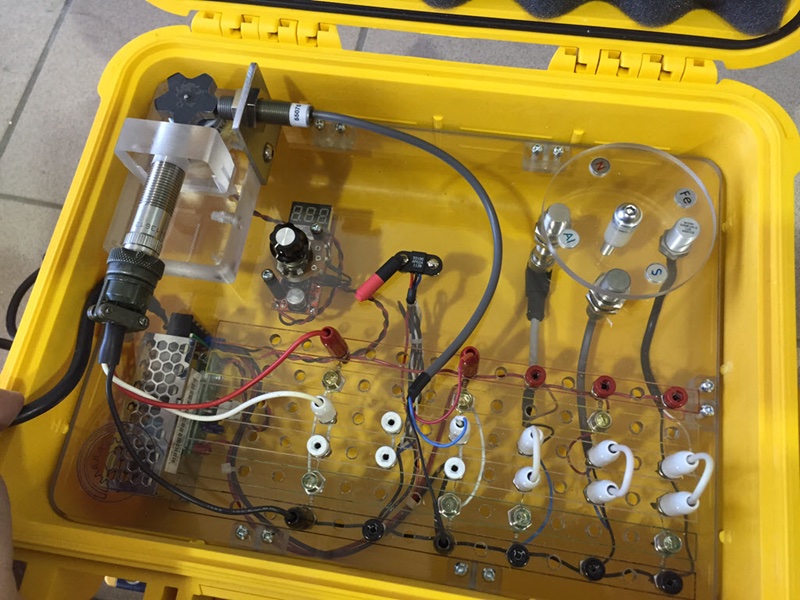

Sensors and Transducers

Objective: Describe the operating principles of typical electrical and electronic devices and components

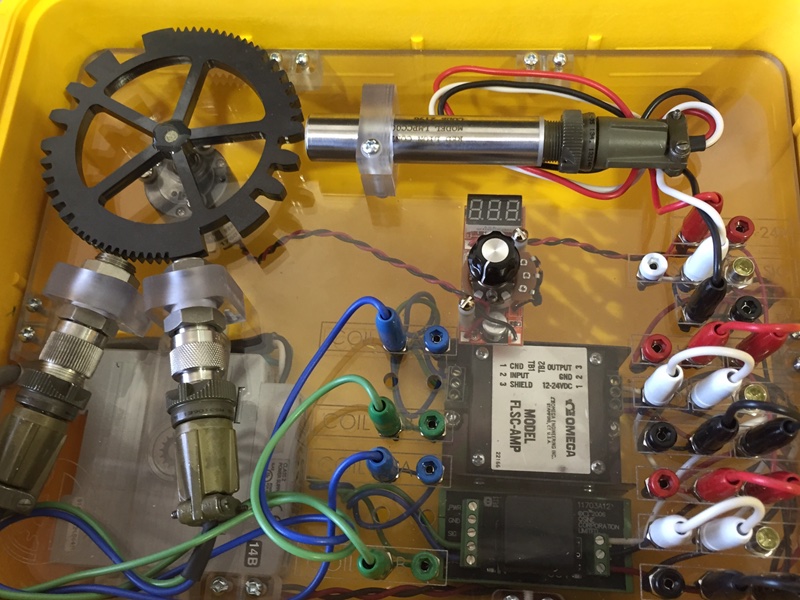

Activities: Test, calibrate and set a pressure switches/transducer, load cell, magnetic pickup and optical encoder

Know your sinking and sourcing and mobile equipment sensor wiring

Hall Effect Sensors

Objective: Describe the Hall effect and its typical application on machinery

Activities: Measure the waveform at high speed to determine output signal integrity

Test various Hall effect sensors with iron, aluminum, north and south pole magnets

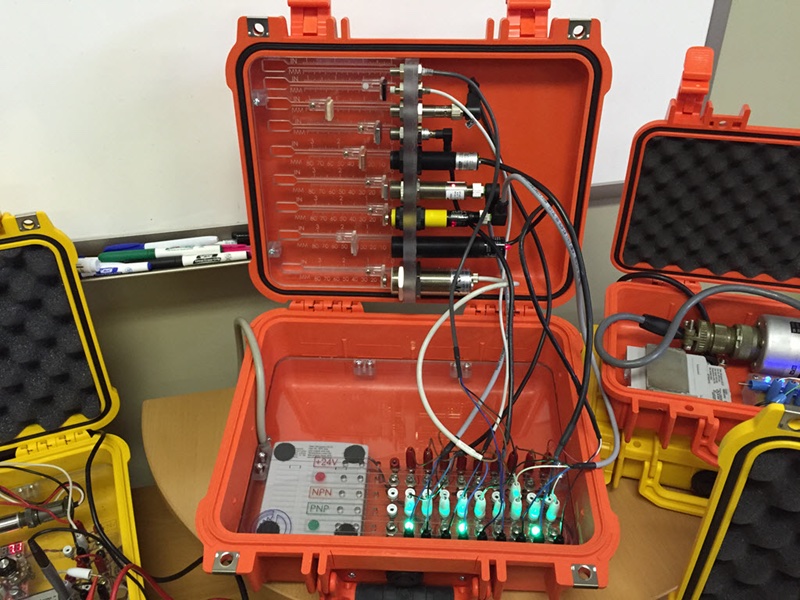

Proximity Sensors

Objective: Explain the operating principles of proximity sensors

Activities: Differentiate between nine different models, by range, types of materials detected, electrical characteristics

Learn to wire proximity sensors correctly, connecting loads to PNP or NPN outputs

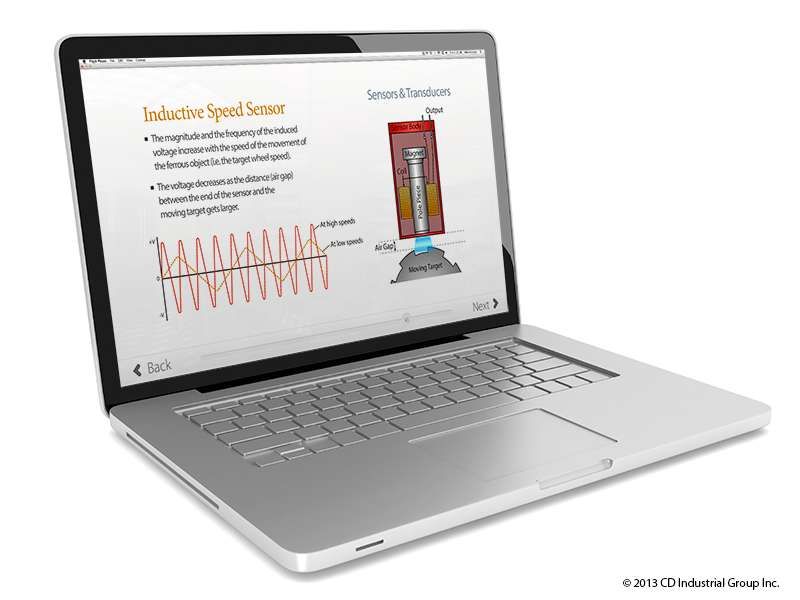

Magnetic Pickups

Objective: Describe the principles of magnetic pickups sensors

Activities: Different between unpowered and powered models

Scopemeter measure the performance of low speed and high speed, 2-wire pickups, connected to amplifiers, and also a self-powered and self-amplified model

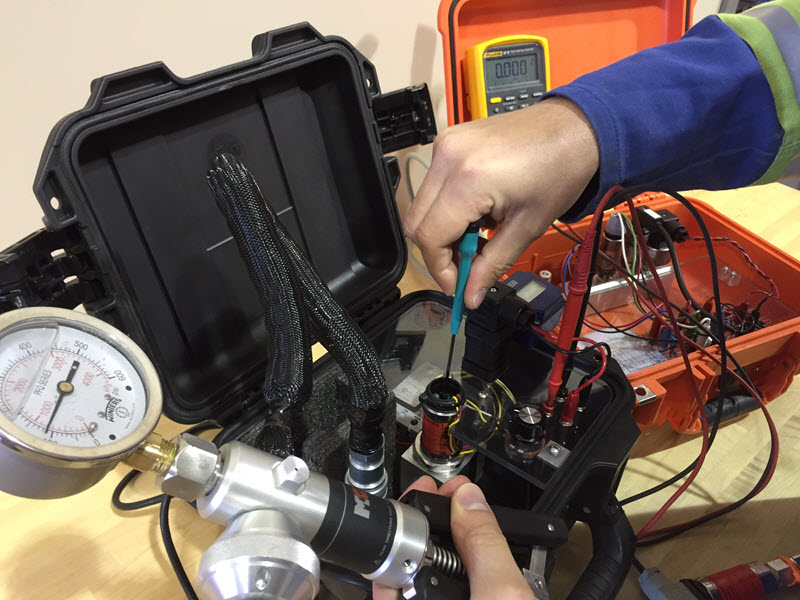

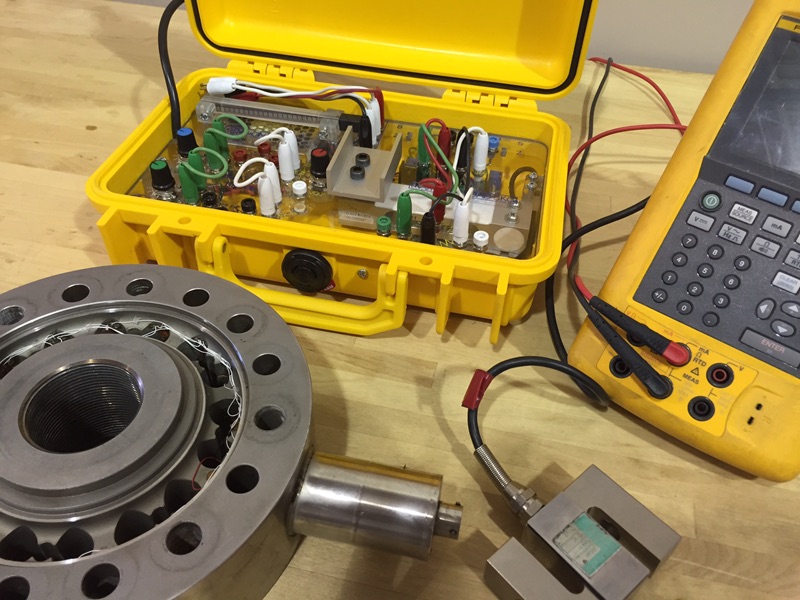

Pressure Transducers and Transmitters

Objective: Describe the function of pressure transducers

Activities: Determine voltage or current output of sensors

Use a multimeter and hand pump to set "Zero" and "Span" on a two-wire pressure transmitter

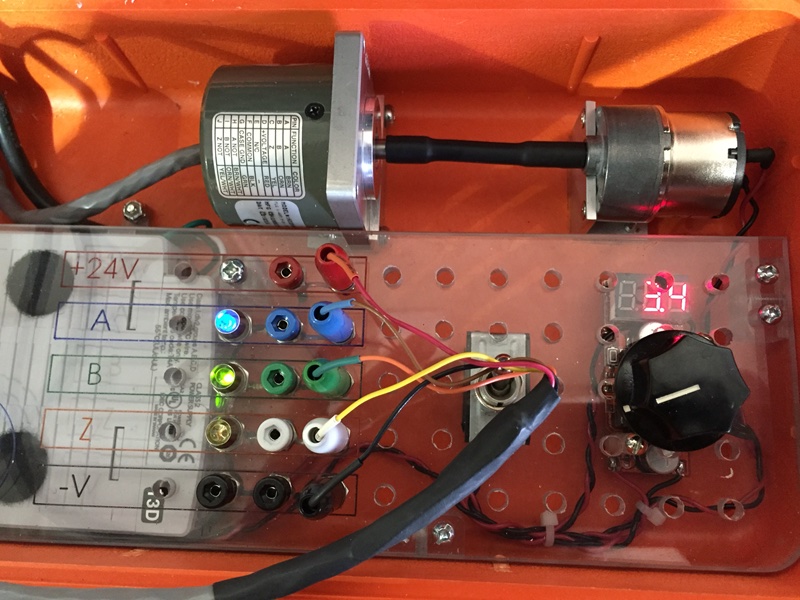

Rotary Optical Encoders

Objective: Explain position sensor technologies

Activities: Troubleshoot and measure output signals of rotary encoders

Differentiate an absolute from an incremental encoder

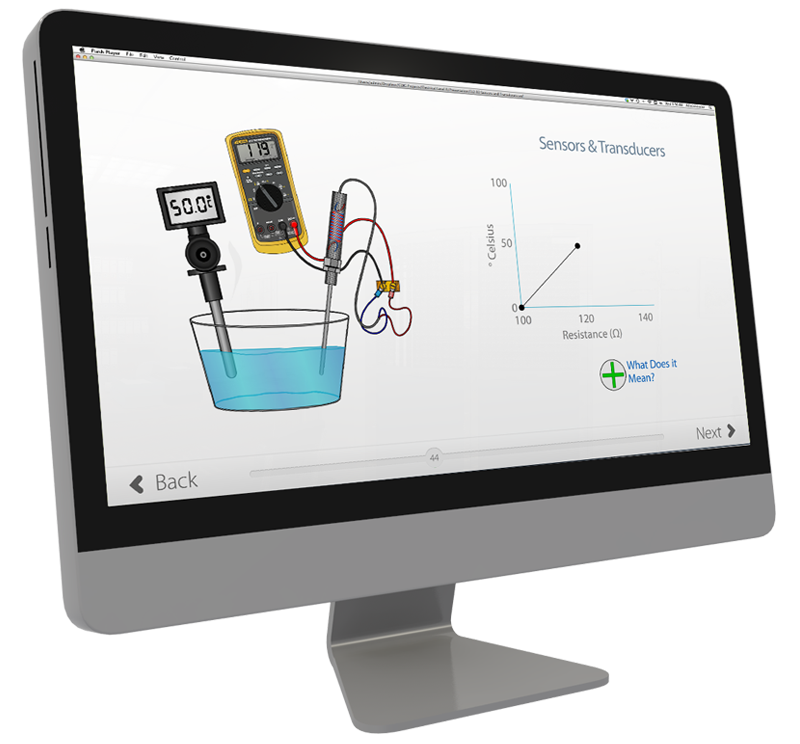

Temperature Transmitters

Objective: Differentiate between RTDs, thermocouples and thermistors

Activities: Explain negative and positive temperature coefficient

Know your RTD and Thermocouple types and how they are wired

Temperature Transmitters

Objective: Differentiate between RTDs and thermocouples and explain transmitter function

Activities: Calibrate RTD and thermocouple transmitters

Use a process calibrator and reference tables to calibrate temperature transmitters

Load Cells

Objective: Explain load cell circuit fundamentals: strain gauge, Wheatstone bridge

Activities: Calibrate a load cell transmitter

Manipulate the branch resistances in a Wheatstone bridge

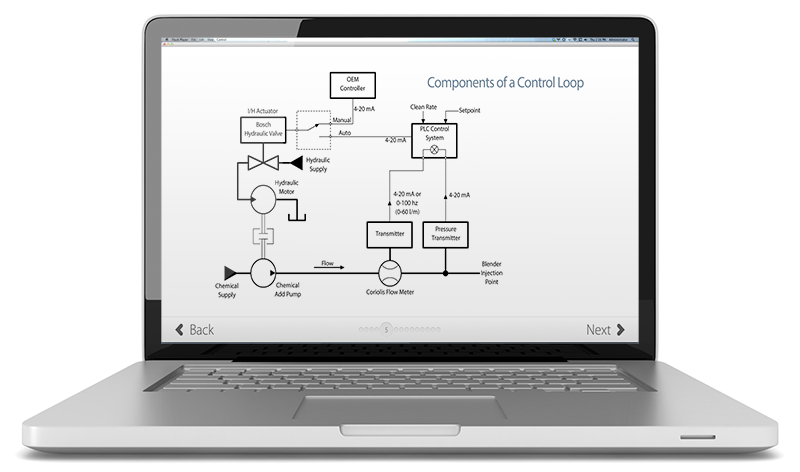

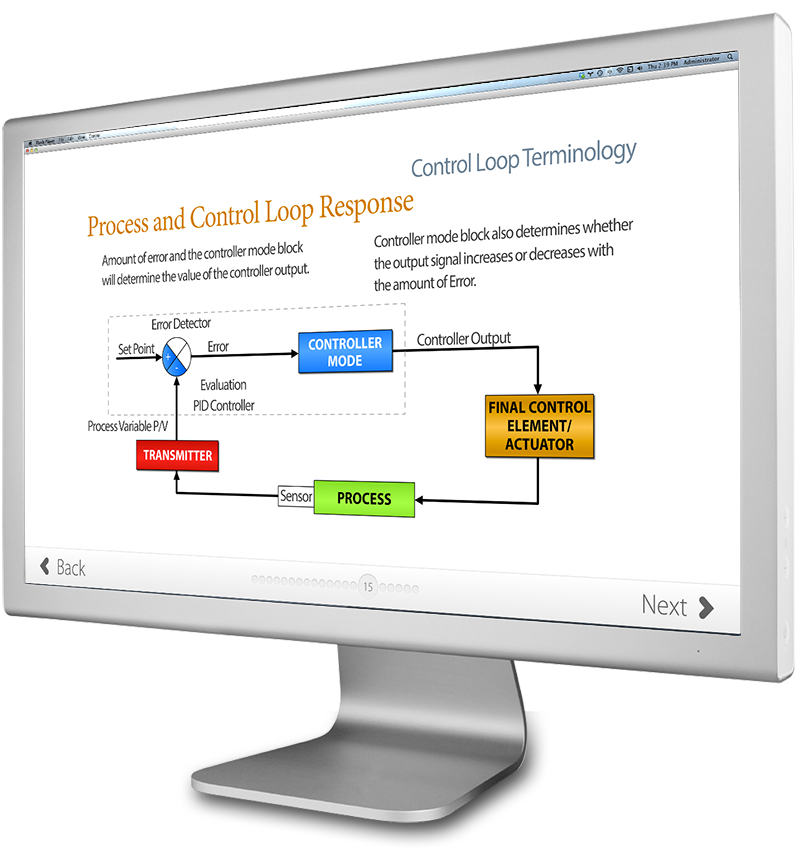

Introduction to Process Control

Objective: Explain the purpose of process control

Activities: Valve control simulation activity

Know your process control terms cold

Control Loops

Objective: Define components and terms used in control loops

Activity: Configure and tune a basic closed control loop

Know your closed, control loops