I learned to use a logical step by step procedure using schematics and test meter to troubleshoot. Quite diverse and challenging. Well worth the time and money.Tim Bond, Electrician, Mitchell's Gourmet Foods, Saskatoon

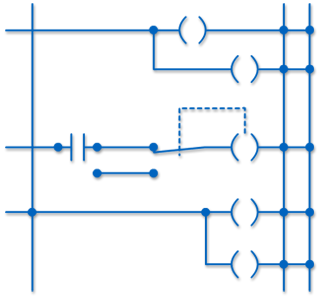

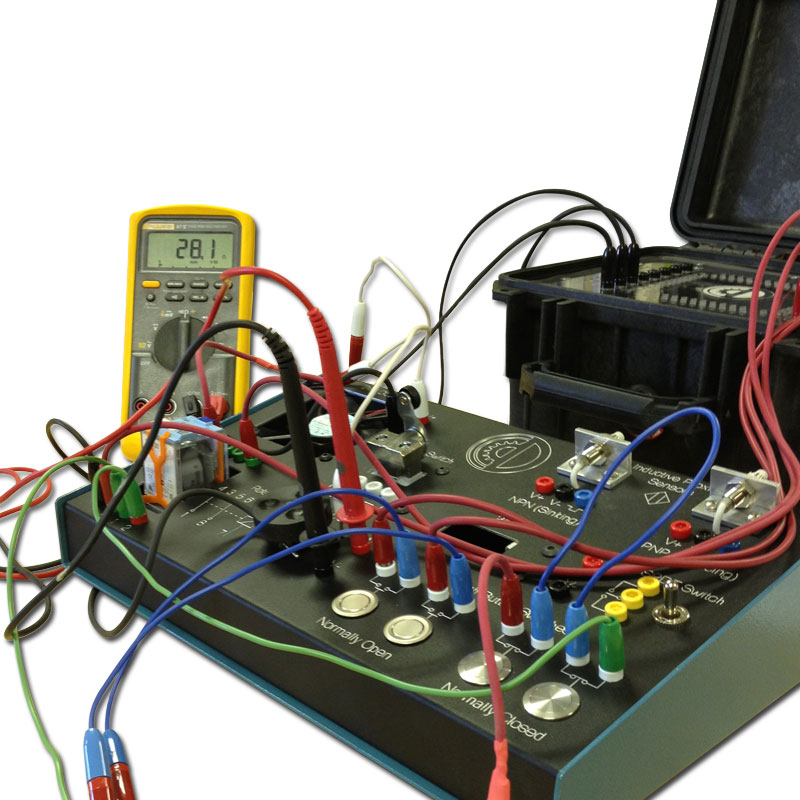

Faulty Control Circuits

Objective: Find open and short circuit faults

Activity: Build typical sensor, relay and coil circuits and then diagnose faults

Work hands-on with our latest fault training panels

Methodical Approach to Troubleshooting

Objective: Troubleshoot an electrical circuit or system following a logical procedure

Activity: Analyze case studies of system faults

Learn the Ten Step Troubleshooting Process

I learned quicker, more insightful troubleshooting. Very comprehensive. Every electrician should take it.Gerald Toporowski, Industrial Electrician, General Motors, Oshawa Truck Plant

Basic Circuit Problems

Objective: Find open and short circuit faults

Activity: Read the logic of a circuit and make an analysis before meter tests are made

A loose wire might be the only problem - avoid part swapping by thinking logically

A good course for developing troubleshooting skills.Willy Grueber, Electrical Supervisor, Epcor Edmonton

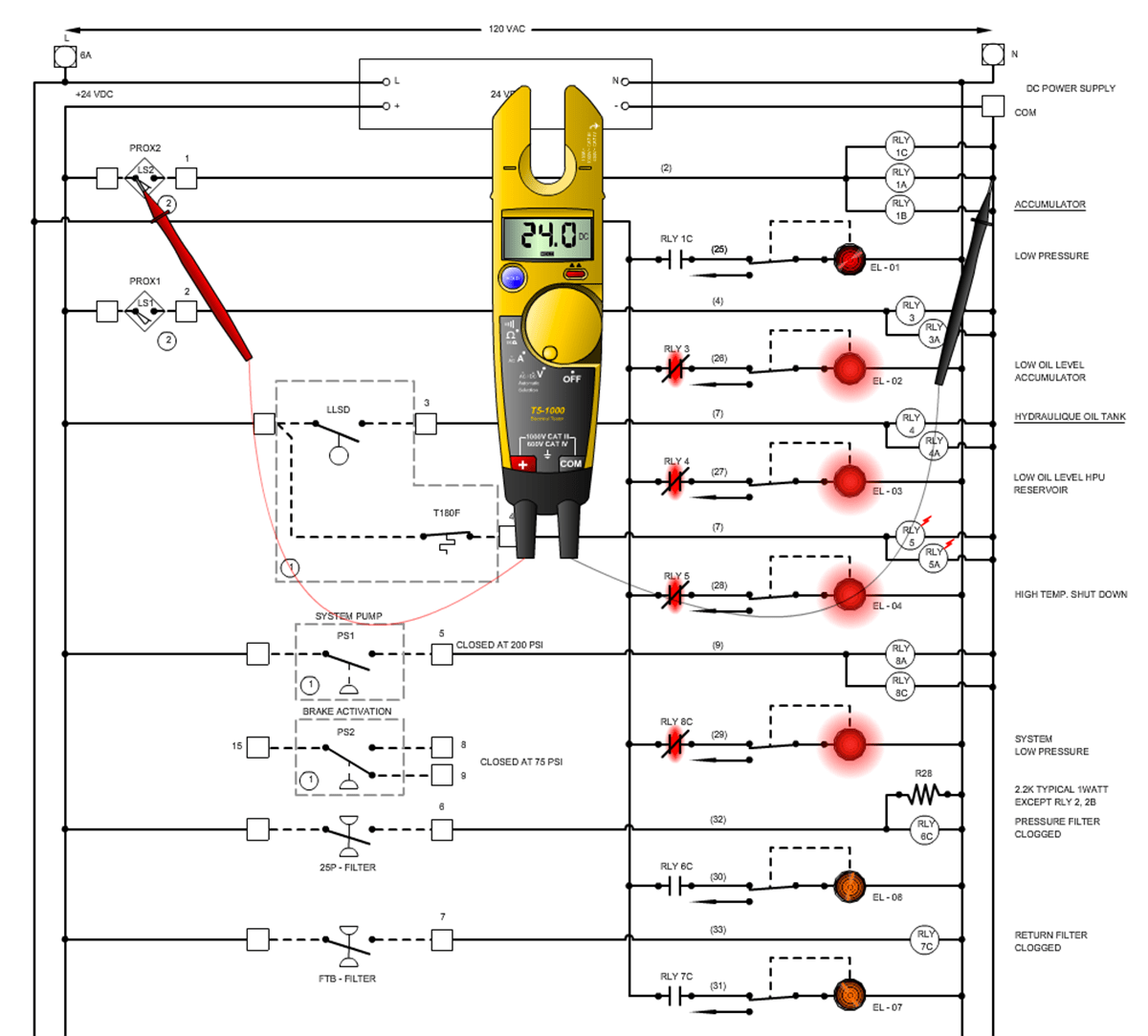

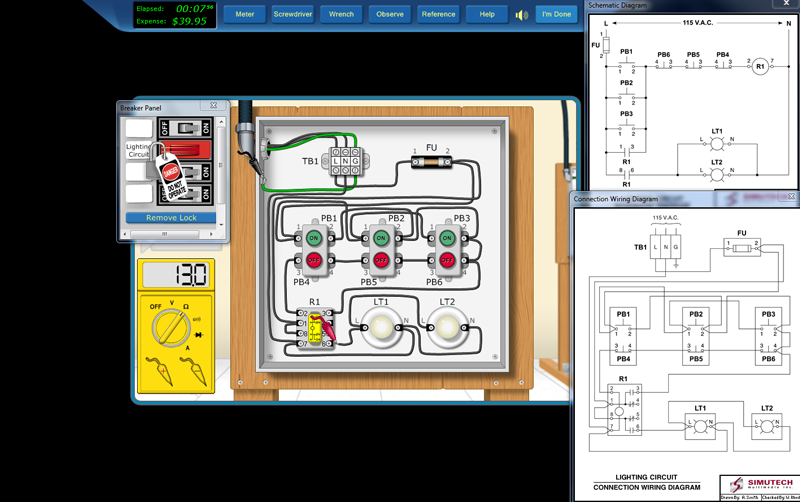

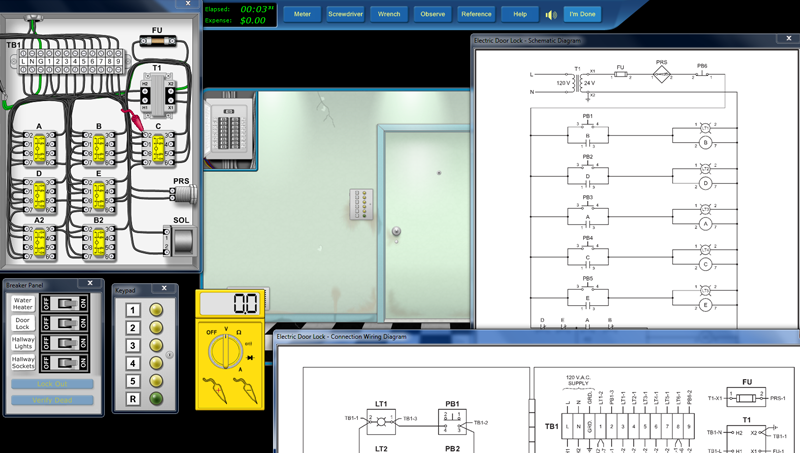

Single Phase Control Systems

Objective: Troubleshoot single phase relay logic control systems

Activity: Analyze faults in a digital lock

Make the minimum number of meter measurements to save time!

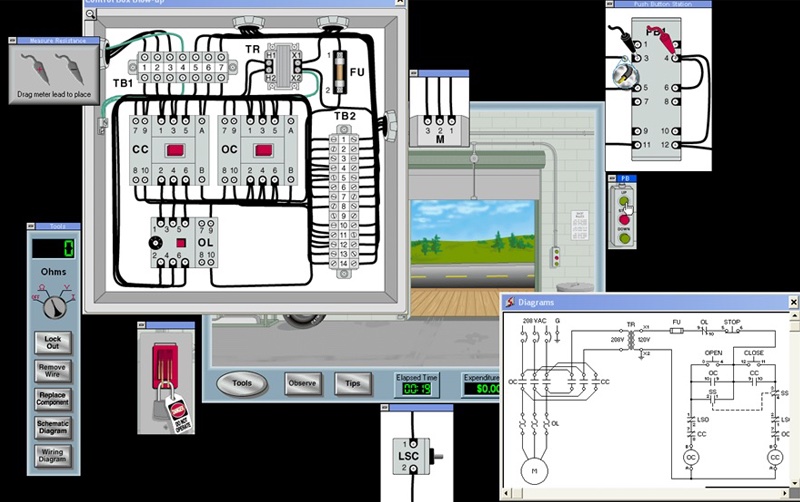

Three Phase Motor Control Systems

Objective: Troubleshoot three phase motor control systems

Activity: Analyze case studies of systems

Troubleshoot by separating the sections of a complex door opener system!

You will learn to reason things out before starting to test with a multimeter. The course had lots of hands-on which was great.Plant Electrician

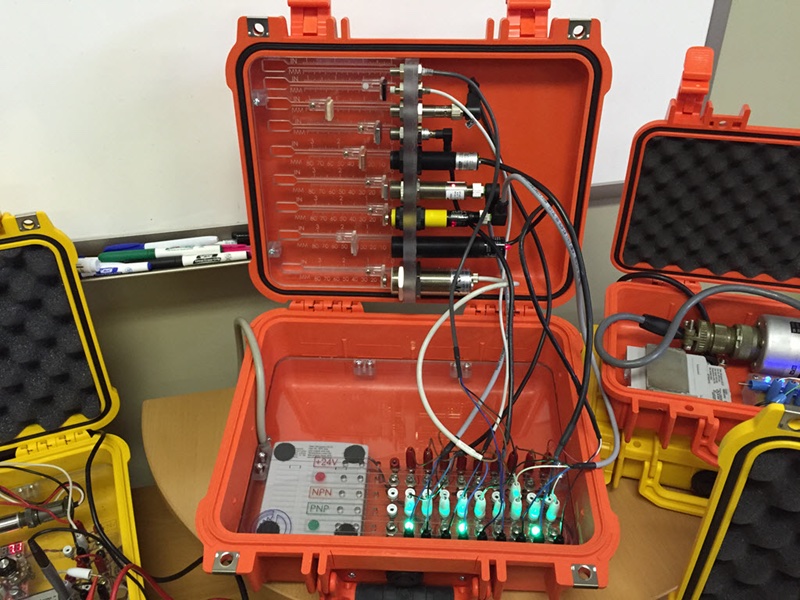

Introduction to Sensors

Objective: Methodically find faults with basic sensor circuits

Activity: Work with three wire proximity sensors in a complex circuit

Know your sensor wiring and related electrical faults!