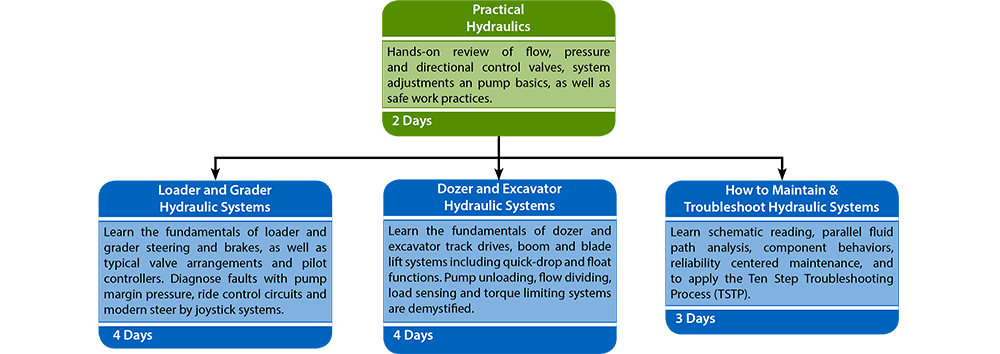

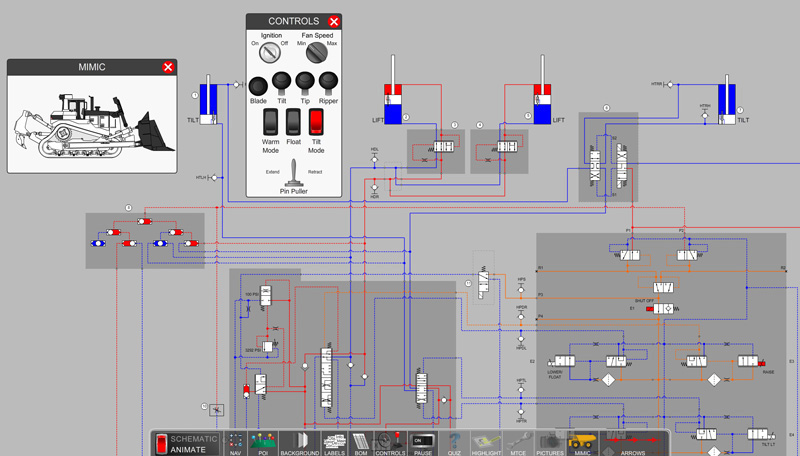

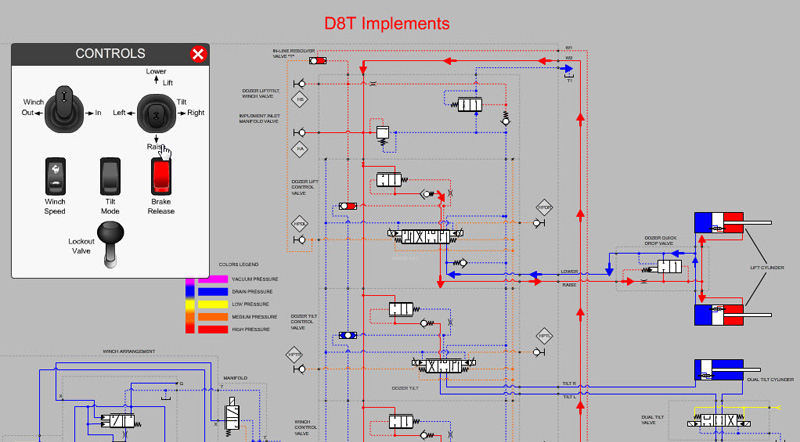

Attachment and Implement System

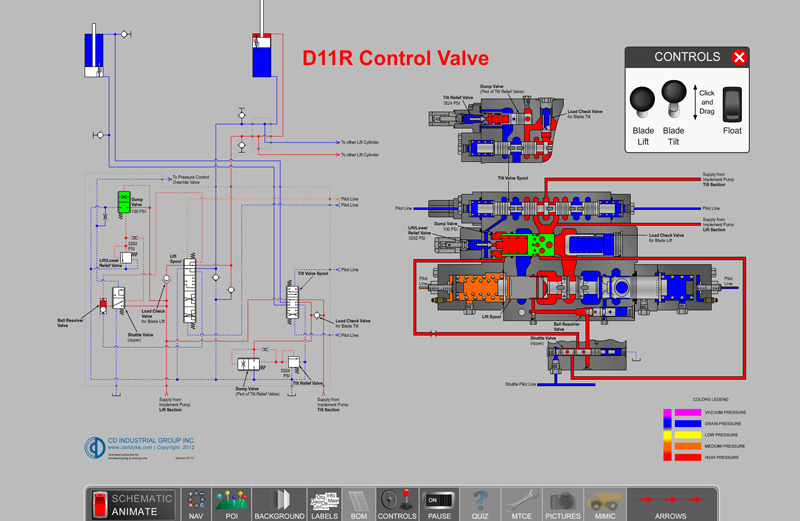

Objective: Analyze implement valve banks and pump controls

Activities: Work out flow paths for dozer blade and boom lift circuits

Know the bucket float and blade quick drop functions cold

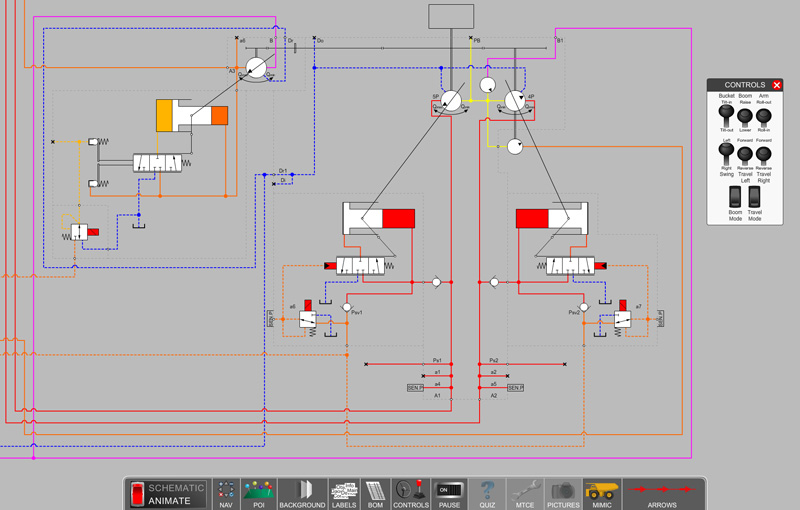

Load Sense Troubleshooting and Proportional Valve Bank

Objective: Explain the features of common load sense directional valves

Activities: Test anti-cavitation, port relief and pilot functions

Differentiate between valve inlet side and outlet side, pressure compensators

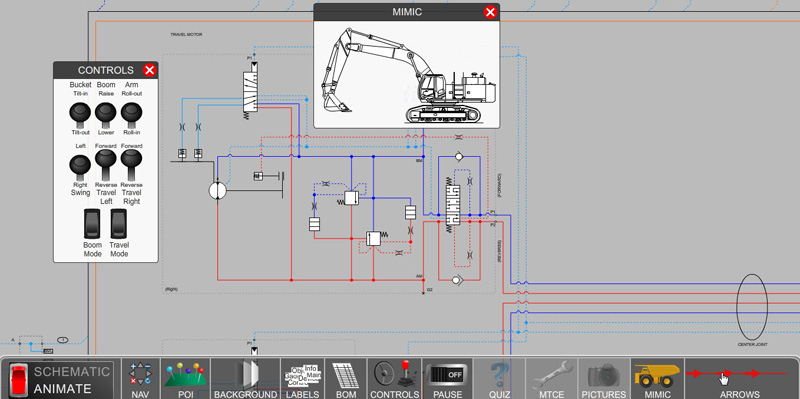

Dozer and Excavator Undercarriage Propel

Objective: Describe typical undercarriage propel and steering clutch circuits

Activity: Analyze typical travel function problems

Solve uneven tracking issues

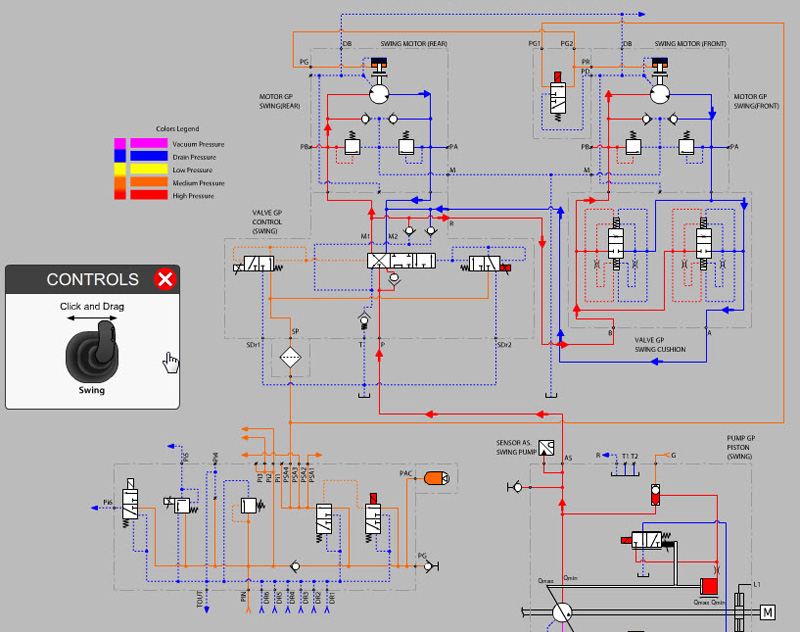

Excavator Swing Circuit

Objective: Interpret swing circuit functions

Activities: Set up and test swing brake valves

Solve swing over-run problems

Pump Controls

Objective: Describe piston pump control systems in use

Activities: Measure standby and margin pressures

Know your horsepower/torque limiting controls

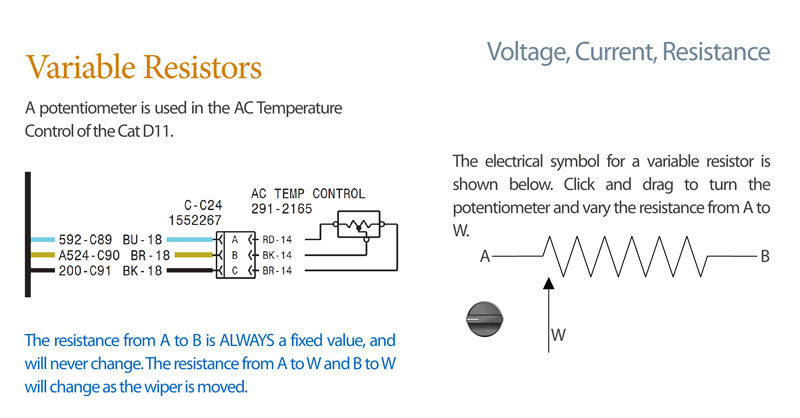

Electrical Circuit Schematics

Objective: Analyze electro-hydraulic component functions

Activities: Identify components and connections by their symbols

Know the valve signals and how to measure them

Safety

Objective: List common hydraulic hazards and safe procedures

Activities: Inspect system components for failures

Work safely around high pressure circuits