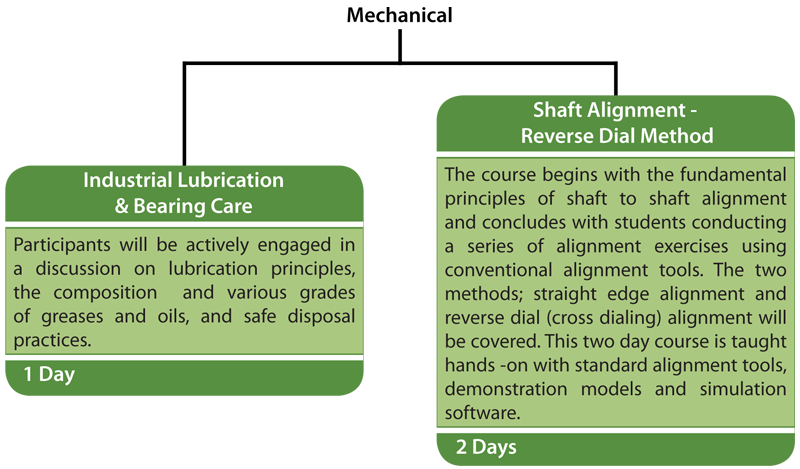

Industrial Lubrication & Bearing Care

Learn to:

- State the cost of incorrect and ineffective lubrication practices on industrial plants

- State the properties of different lubricants and their additive chemicals

- Describe the relationship between speed, temperature and loading as it relates to lubricant performance

- Select the correct lubricant for a given machinery application

- List factors that shorten bearing life and identify their effects

- State correct lubrication practices for specific plant machinery

- Describe safe methods of working with lubrication

Proper lubrication practices are vital to the longevity of bearings and machinery parts. This course is intended for maintenance personnel and machinery operators who have responsibility for lubrication systems. Participants will be actively engaged in a discussion on lubrication principles, the composition of greases and oils and the various grades as well as safe disposal practices. Demonstrations of oil viscosity performance using specially machined plates will allow participants to directly experience and appreciate wear issues. Case histories of bearing damage and its lubrication related causes will be covered using slides and a collection of actual bearing elements. A variety of lubrication systems will be examined along with reports from oil analysis laboratories.

Topics

- Lubrication Issues

- Oil & Grease Science

- Tribology

- Selection of Lubricants

- Maintenance Concerns

- Lubrication Practices

- Safety

Where does this class fit in?

Industrial Lubrication & Bearing Care is a stand-alone class in our mechanical training. You might also be interested in Shaft Alignment - Reverse Dial training. From there, you could go on to Rim and Face, and then Laser Shaft Alignment Training.